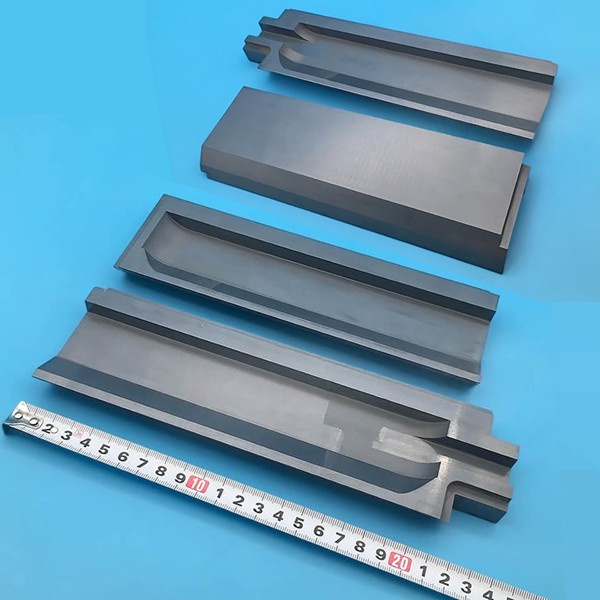

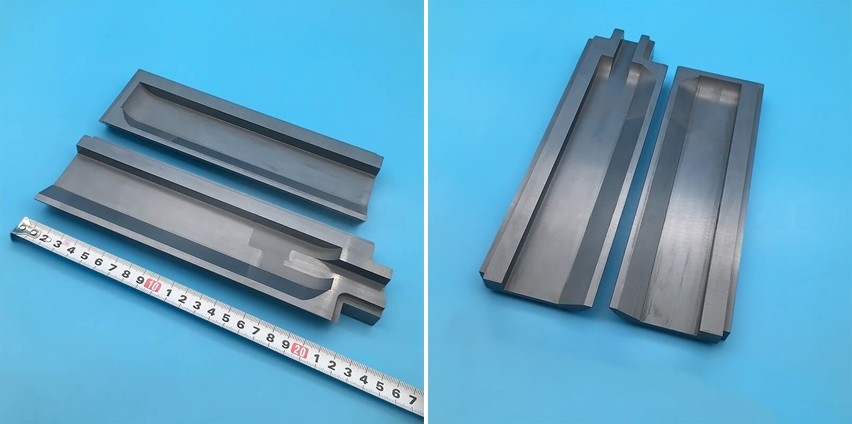

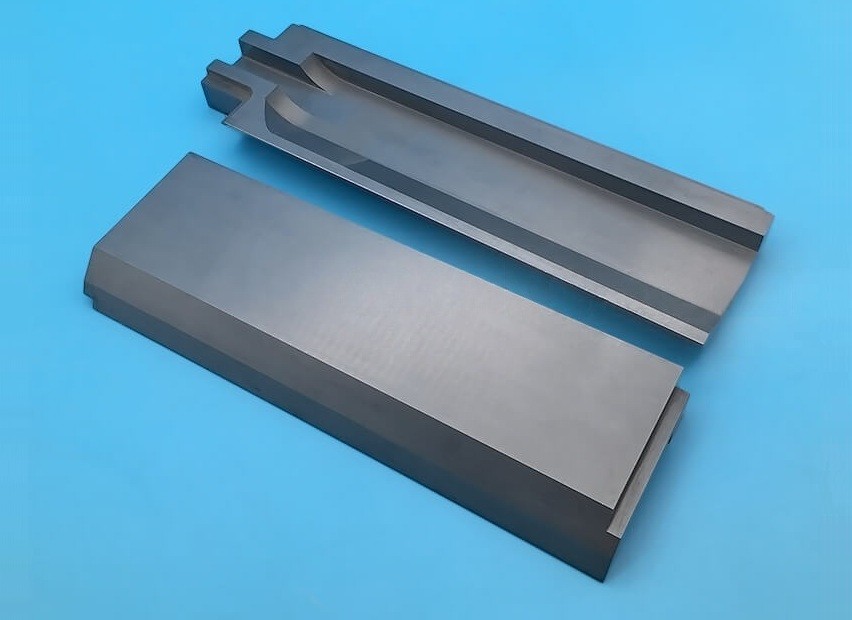

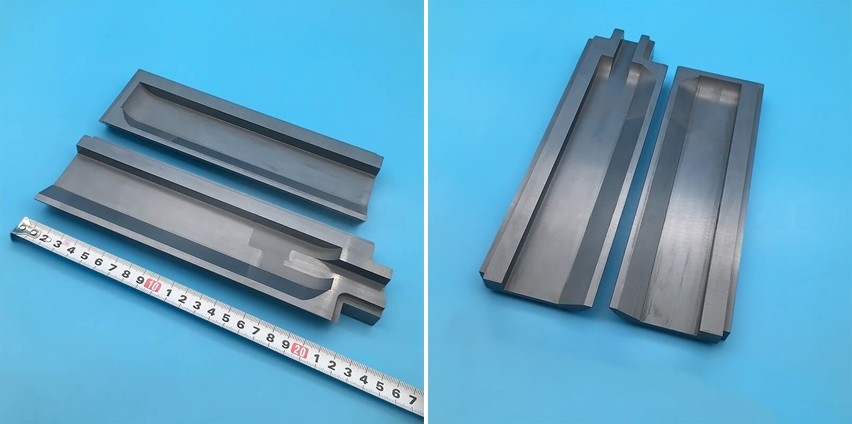

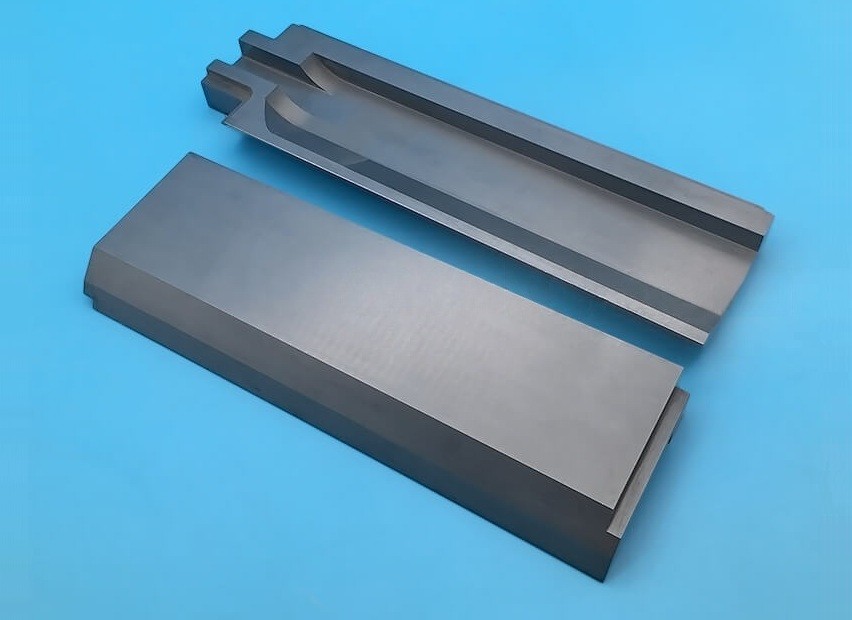

Silicon carbide ceramic molds

Alias: high-temperature and pressure resistant ceramic jigs

Description:

Customized silicon carbide (SiC) ceramic molds are also known as high-temperature and pressure-resistant ceramic fixtures. These ceramic molds, with their precise shapes and smooth surface designs, ensure a high degree of accuracy and consistency during use. The high hardness and strength of silicon carbide ceramics allow these molds to maintain their shape and performance under high temperature and pressure conditions, thereby ensuring product quality and production efficiency.

Features:

Silicon carbide ceramic molds (Alias: high-temperature and pressure resistant ceramic jigs), which are specifically tailored tools for various high-temperature and high-pressure manufacturing processes, are suitable for extreme environmental conditions.

1. Precise shape and smooth surface design

It ensures a high degree of accuracy and consistency in the manufacturing process, thereby optimizing production quality and efficiency.

2. High temperature and high pressure performance

Silicon carbide ceramics have excellent mechanical strength (compressive strength up to 2600 MPa) and hardness (2100HV1), and are able to maintain their shape and function at high temperatures (up to 1600℃) and high pressure environments.

3. Superior thermal performance

High thermal conductivity (100W/m·K) and low coefficient of thermal expansion (4 x10-6K-1) make the mold stable during rapid heating and cooling, and is not easy to crack or deform.

4. Corrosion resistance

The chemical stability of silicon carbide materials allows molds to excel in handling various chemicals and high-temperature molten materials, making them suitable for metal casting, glass forming, and high-temperature chemical reactions.

Applications:

1. Metal Casting and Machining

It is used in high-temperature metal casting and melting, especially in the production of cast iron, steel and non-ferrous metals.

2. Metal Casting and Machining

Molding ceramic and glass products at high temperatures ensures the shape and dimensional accuracy of the products.

3. Chemical industry

It is used in high-temperature chemical reactions, processing reactants and catalysts, especially suitable for acid and alkali resistance and other corrosive environments.

4. Advanced material research and development

In the development and testing of new materials, it is used to evaluate and test the properties of materials under high temperature conditions.

With their high reliability and performance, silicon carbide ceramic molds offer irreplaceable value in modern industrial applications, especially in high-temperature and high-pressure environments that require highly precise control and durability. These molds not only enhance production efficiency but also improve the quality of the final product, making them indispensable tools in high-temperature industrial applications.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.