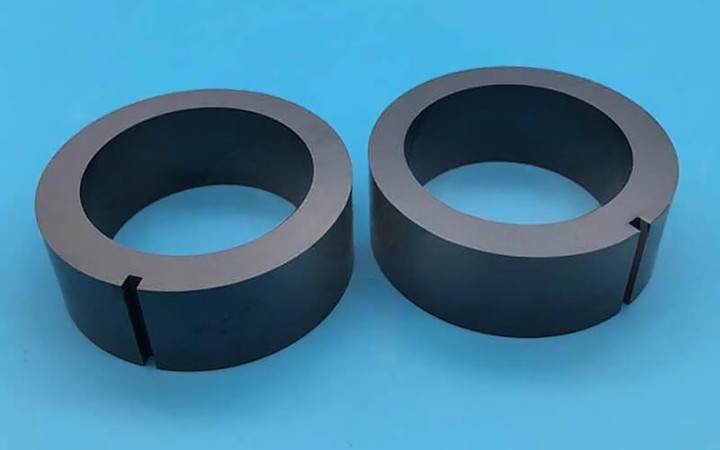

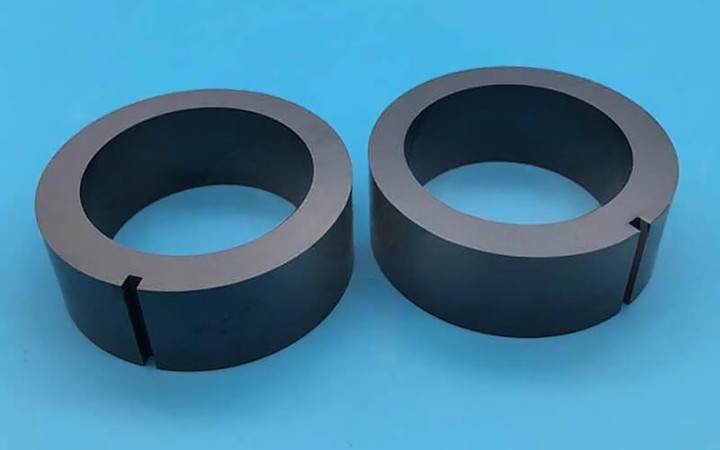

Silicon carbide ceramic segmented seal ring

Alias: Split isolated ceramic sleeve

Description:

Customized silicon carbide (SiC) ceramic segmented seal rings, also known as isolated ceramic sleeves. These silicon carbide ceramic rings are widely used in demanding industrial applications due to their excellent mechanical properties, wear resistance, and corrosion resistance, especially in environments requiring high strength and durability. These ceramic rings feature multiple petals design, which makes them more convenient when installing and disassembling.

Features:

Silicon carbide ceramic segmented seal rings (Alias: Split isolated ceramic sleeves) are critical components designed for high-end industrial applications, especially in environments requiring extremely high mechanical properties and wear resistance.

1. High wear resistance and hardness

The hardness of silicon carbide materials reaches 93HRA and 2100HV, allowing these rings to exhibit excellent wear resistance and scratch resistance when dealing with high-hardness materials.

2. Excellent mechanical strength

With a flexural strength of 400MPa and a compressive strength of 2600MPa, silicon carbide ceramic rings are capable of maintaining stability and integrity in high-pressure environments.

3. Low coefficient of thermal expansion and high thermal conductivity

The coefficient of thermal expansion is 4 x 10-6K-1 and the thermal conductivity is 100 W/m ·K, ensuring the stability and efficiency of the material in environments with large temperature changes.

4. Thermal shock resistance

The stable performance of 400°C thermal shock makes these ceramic rings less prone to breakage during rapid temperature changes, making them suitable for high-temperature processes.

5. Segment-petal design

Easy to install and remove, especially suitable for use in systems that require frequent replacement or maintenance.

Applications:

1. Mechanical seals and bearings

Used as a sealing ring in pumps and other fluid handling equipment to keep systems running efficiently and prevent liquid leakage.

2. Grinding and polishing equipment

As a key component of grinding or polishing equipment, it is used to handle hard materials and ensure the quality of machining.

3. High temperature industrial equipment

Used in industrial furnaces and heat treatment equipment where high temperature resistance and mechanical stability are required.

4. Chemical and material processing

In chemical processing and processing of high-temperature materials, silicon carbide's chemical inertness makes it an ideal choice.

Silicon carbide ceramic segmented seal rings, with their high wear resistance, excellent mechanical strength, and excellent thermal stability, play a crucial role in high-precision and demanding industrial fields. The design and performance of these rings make them valuable in modern industrial technology applications, especially suitable for high-temperature, high-pressure, and high-wear environments, ensuring long-term reliability and efficient performance of equipment.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.