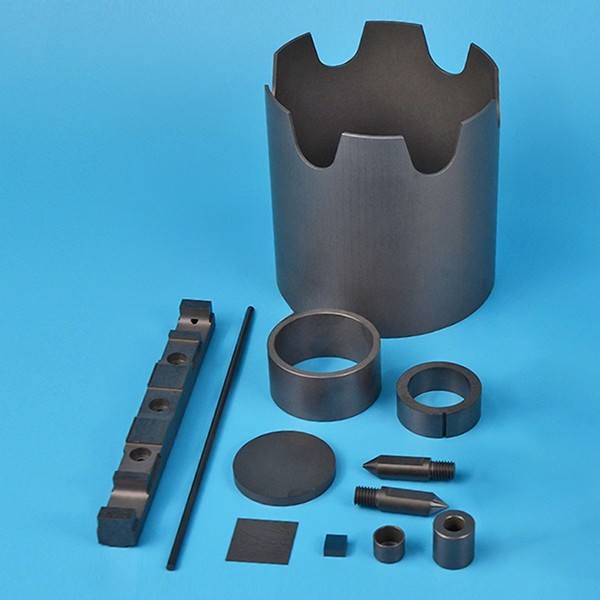

Silicon carbide ceramic parts

Alias: silicon carbide ceramic products

Description:

Silicon carbide ceramic products have attracted much attention due to their unique physical properties and excellent heat resistance. In industry and technology, silicon carbide ceramics are often used to manufacture components in high-temperature, high-pressure, and high-wear environments. Its high hardness, corrosion resistance, and exceptional thermal conductivity make it an ideal material for fields such as semiconductors, aerospace, and energy.

In addition, silicon carbide ceramics are also widely used in the manufacturing of chemical equipment and mechanical parts, and their high-temperature strength and chemical stability provide reliable guarantees for these applications.

Material introduction:

Silicon carbide material is mainly composed of SiC, it is a high-performance ceramic material with superior corrosion resistance, which is widely used in mechanical seals and pump valve parts due to its excellent high-temperature stability, conductivity and corrosion resistance, and is used to manufacture high-temperature parts in petrochemical, aerospace and automotive industries.

The excellent performance of silicon carbide directly promotes the continuous development of industrial technology and provides reliable solutions for industrial production.

Features:

1. Excellent high-temperature strength

Silicon carbide ceramic components maintain their strength (high temperature stability > 1400°C) at extremely high temperatures, making them ideal for many high-temperature applications.

2. Excellent thermal conductivity

Silicon carbide ceramics have extremely high thermal conductivity and electrical semiconductor properties, which makes them widely used in the electronics industry and high-power appliances. As an excellent thermal conductive material, its thermal conductivity (120W/m · K) higher than many metals. This makes it useful in applications that require efficient heat dissipation.

3. Electrical semiconductor performance

Silicon carbide materials have semiconductor properties, with high electron mobility and low resistivity, making them excellent in power electronics.

4. High hardness and corrosion resistance

Silicon carbide ceramics have excellent chemical and physical stability, exhibiting high hardness (hardness 9.5 Mohs) and corrosion resistance.

4.1 High hardness

Silicon carbide is close to diamond's hardness, making it highly resistant to wear and scratch, making it useful in manufacturing wear-resistant components and cutting tools.

4.2 Corrosion resistance

Due to its chemical inertness, silicon carbide material has good corrosion resistance to many chemicals, allowing it to be used stably for a long time in chemical and liquid treatment equipment.

Applications:

The versatility and excellent performance of silicon carbide make it widely used in many fields, including high-temperature industry, electronic devices, mechanical engineering, and chemical fields. Its high-temperature stability, thermal conductivity, semiconductor properties, as well as high hardness and corrosion resistance, make it a very important engineering material, driving technological development and innovation in various fields.

1. High-temperature industrial applications

Silicon carbide parts are widely used in high-temperature industrial fields, such as furnaces, heat treatment equipment, and high-temperature reactors. Its high-temperature strength and stability allow it to maintain its structural integrity at temperatures up to 1400°C and beyond, withstanding extreme thermal stress and pressure. Specifically, it includes: high-efficiency kiln tools, roller kiln silicon carbide rollers, and firing plates (> 1400°C), which improve thermal conductivity and reduce energy consumption by 25%. High-temperature heating element, silicon-molybdenum furnace heating element (Si C rod), 3 times longer life than traditional alloys. Metallurgical refractory materials, aluminum electrolytic-cell inner-lining, molten steel deoxidizer, reduce impurity pollution. Silicon carbide high-temperature furnace heating elements used in industries such as material sintering, heat treatment and glass manufacturing.

2. Electronic and electrical fields

Silicon carbide ceramics are used in semiconductor power devices, offering lower losses and higher efficiency in high-temperature and high-frequency environments. Including: power semiconductor substrates, SiC MOSFET/IGBT chip substrates for manufacturing electric vehicle inverters and charging piles, which can withstand high voltage (> 10kV) and reduce energy consumption by 30%. RF device carrier, the heat dissipation substrate of the microwave RF front-end module of the 5G base station, supports high-frequency signal transmission. Wafer manufacturing consumables, CVD trays for semiconductor chemical vapor deposition, etch rings, etc.

3. Mechanical cutting industry

Silicon carbide ceramics can be used to manufacture carbide grinding tools such as green silicon carbide grinding wheels (GC), cutting lines, for single crystal silicon slicing (photovoltaic industry) and carbide grinding. Precision bearing components, silicon carbide ceramic bearing balls, sealing rings, friction coefficient < 0.01 without lubrication.

4. Petrochemical and metallurgical fields

Silicon carbide ceramics can be made into corrosion-resistant reaction parts, liners of desulfurization reactors, catalytic cracking device nozzles, and resistance to H₂S and acid corrosion. High-precision filtration system, silicon carbide ceramic membrane (filtration accuracy 1 nm), used for oil and gas separation, wastewater treatment, with a lifespan of 5 times that of polymer membrane. Wear-resistant conveying parts, slurry pump impeller, cyclone liner, wear resistance is 20 times that of steel. Refractory materials and components include blast furnace linings, crucibles, and ceramic heat exchangers to improve equipment durability and thermal efficiency.

5. Aviation & Aerospace

Silicon carbide ceramic high-temperature components, including thermal structural components, such as rocket engine nozzles, gas turbine blades (SiC-CMC silicon carbide matrix composites), reduce weight by 40% and withstand temperature > 1500℃. Thermal protection system, spacecraft re-entry insulation tiles, combustion chamber lining, thermal shock resistance > 500 cycles (ΔT=1000℃).

6. Automotive industry

Silicon carbide ceramics are increasingly used in the automotive industry, such as the heat dissipation substrate of the electric vehicle drive module (> 400V system) at the core of the automotive electronic control system, and the thermal conductivity is 300% higher than that of alumina ceramics. silicon carbide ceramic brake discs for brake and power components (weight reduction by 50%); Turbocharged rotors are able to improve engine efficiency and reduce emissions.

7. Energy sector

It is used in new energy equipment such as solar panels, generator insulation pads, and electric heating connectors, because it can withstand high temperature and high voltage and has good electrical insulation.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.