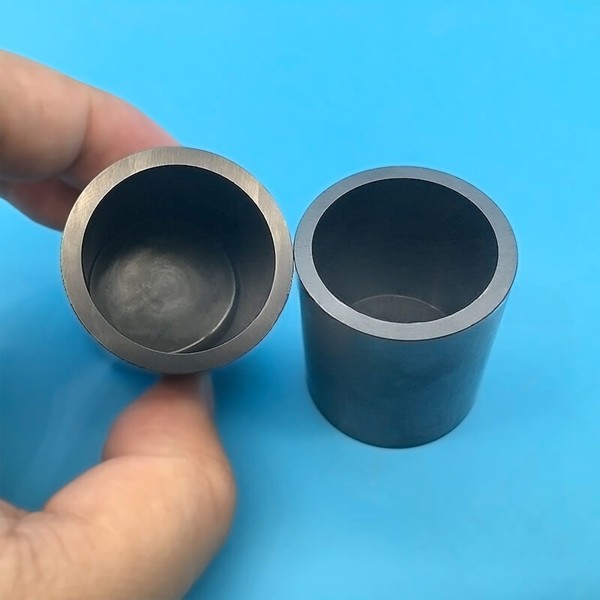

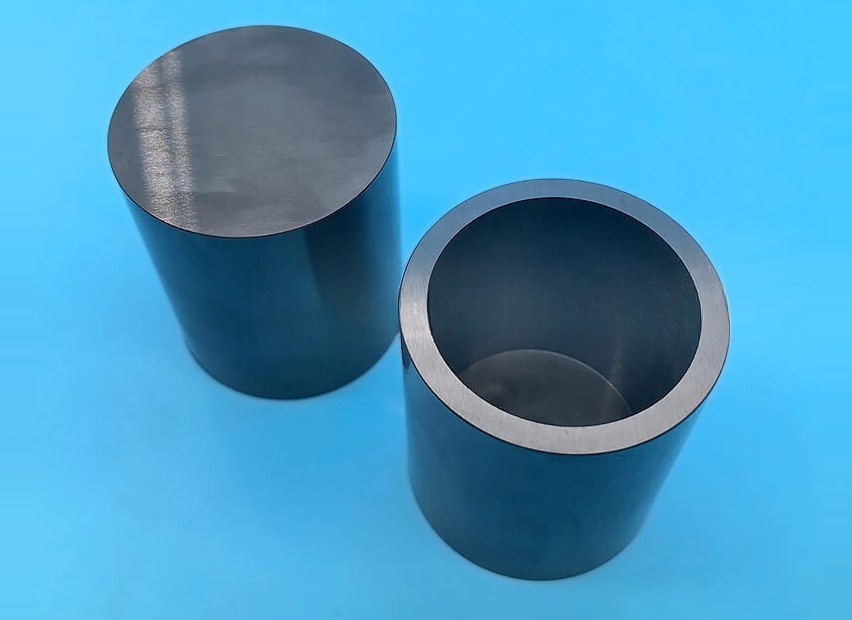

Small silicon nitride ceramic crucible

Alias: Laboratory Melting Crucible / Processed Ceramic Sleeve

Description:

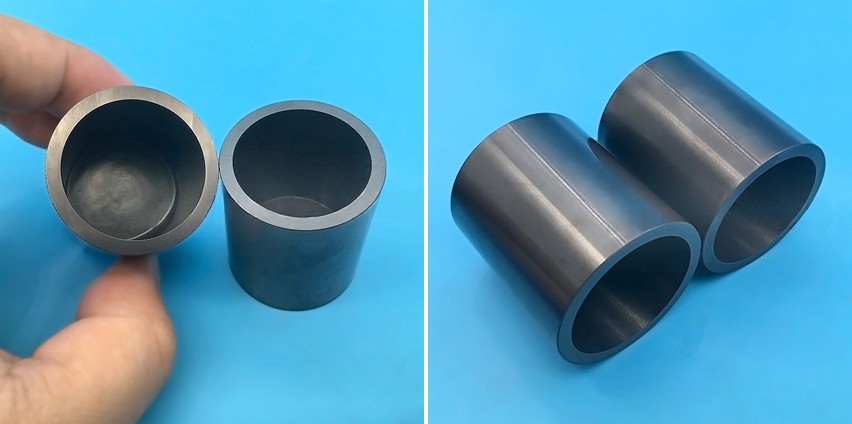

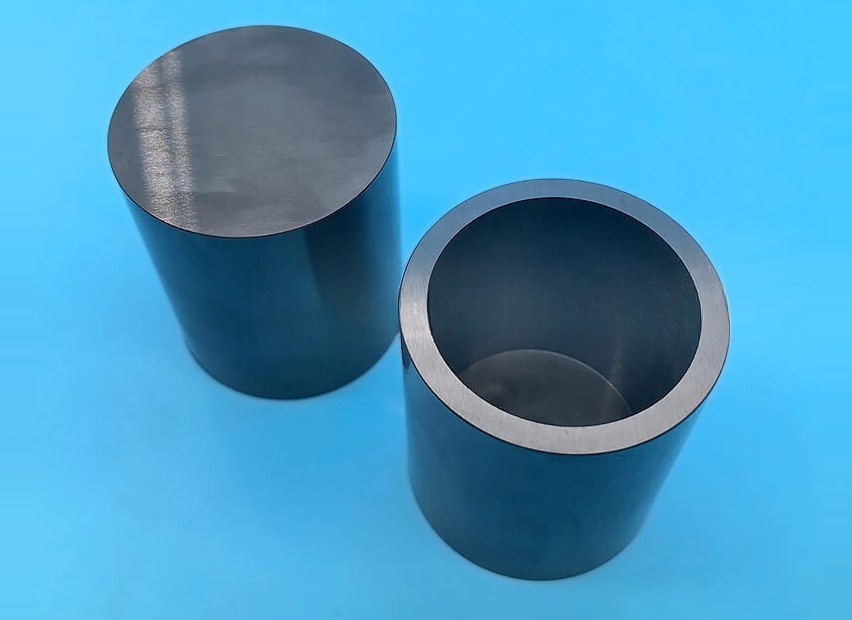

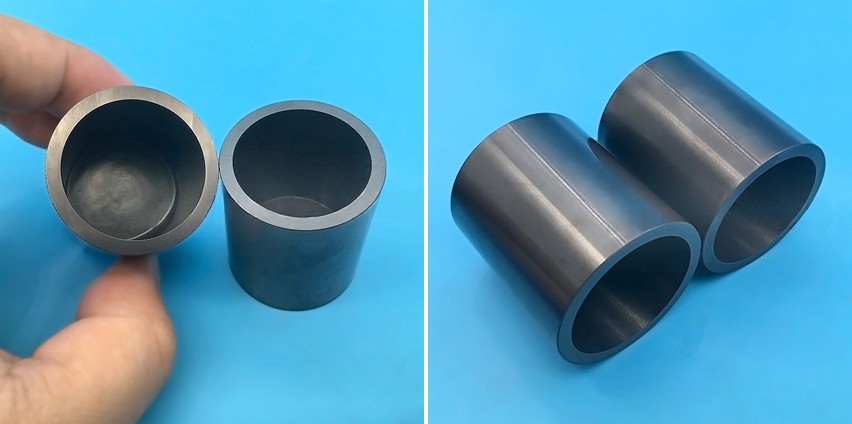

Customized small silicon nitride (Si3N4) ceramic crucibles, also known as laboratory melting crucibles. This type of ceramic crucible is widely used in various high-temperature experiments and industrial melting processes, especially in laboratory settings, due to its excellent high-temperature performance, corrosion resistance, and thermal stability. These crucibles feature smooth interior and exterior surfaces and uniform wall thickness designs to ensure stability and durability at high temperatures.

Features:

Silicon Nitride Ceramic Crucible (Alias: laboratory melting crucible), is designed for laboratory and high-temperature industrial applications for conducting smelting and chemical experiments. The superior physical and thermal properties of silicon nitride (Si3N4) make it ideal for handling high-temperature materials.

1. High temperature performance

Silicon nitride materials can withstand temperatures up to 1200°C, and their high thermal stability and heat resistance ensure reliable use under extreme conditions.

2. Corrosion resistance

Silicon nitride is extremely resistant to a wide range of chemicals, making it suitable for handling a wide range of chemical reactions, including acidic and alkaline substances.

3. Thermal shock stability

It has extremely high thermal shock stability (500 for △T℃) and can withstand rapid temperature changes without cracking or damage.

4. Structural design

Crucibles are often designed with a center hole and other shapes to accommodate specific usage requirements, increase versatility, and increase experimental flexibility.

5. Physical strength

High flexural strength (600MPa) and compressive strength (2500MPa), ensuring that shape and function are maintained under physical load.

Applications:

1. Laboratory research

It is widely used in chemistry and physics laboratories in universities and research institutions to conduct high-temperature chemical analysis and materials science experiments.

2. Industrial smelting

In the metalworking and ceramic manufacturing industries, it is used to melt metals and other materials with high melting points.

3. High temperature furnace application

Used in high-temperature furnaces as melting vessels for melting glass or special alloys.

4. Chemical equipment

Used as a reaction vessel in chemical production, especially in processes requiring extreme temperatures and chemical stability.

Small silicon nitride ceramic crucibles, with their exceptional high-temperature resistance, corrosion resistance, and thermal stability, play a pivotal role in laboratory and industrial high-temperature applications. These crucibles not only provide excellent experimental and production support but also become indispensable tools in modern scientific research and industrial production due to their high reliability and versatility.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.