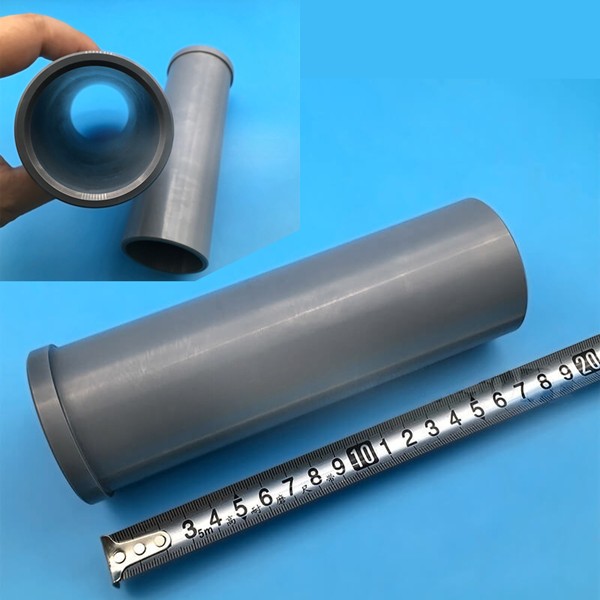

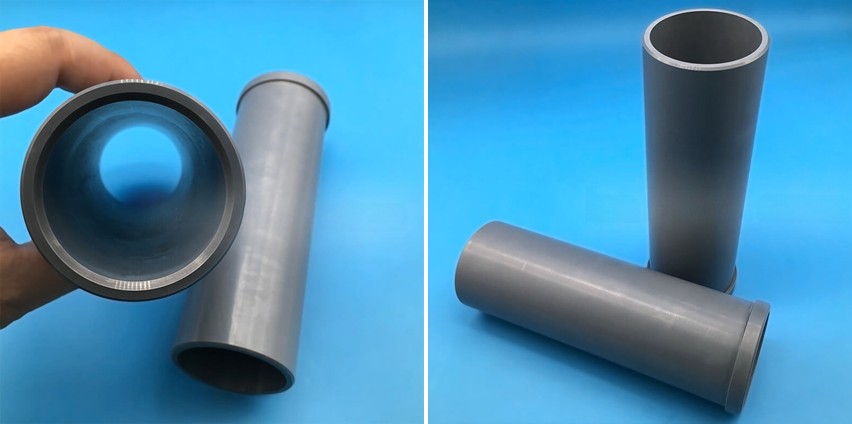

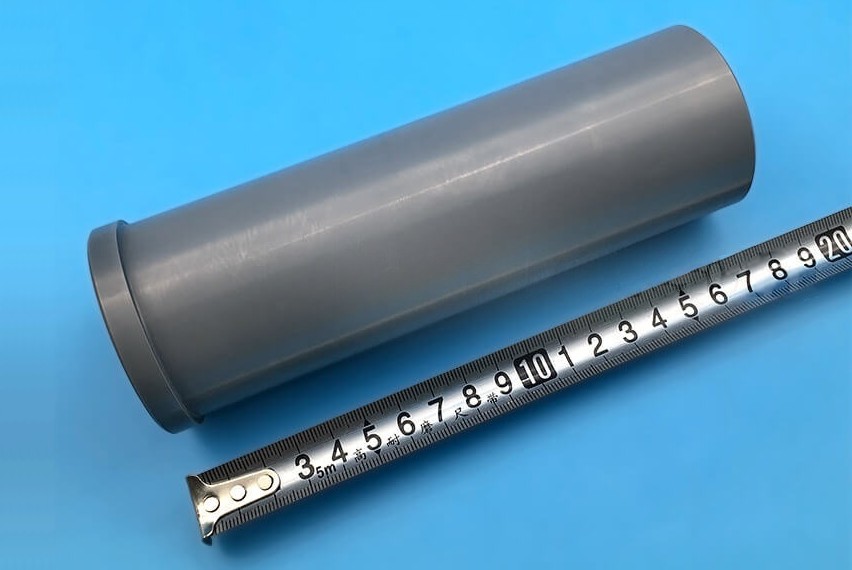

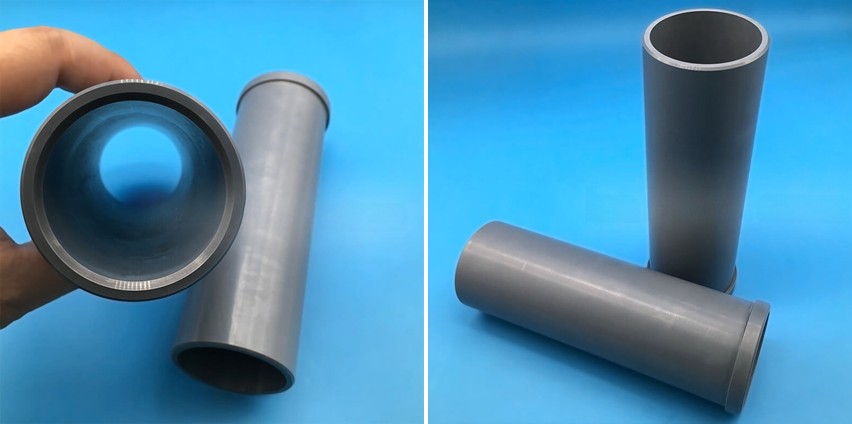

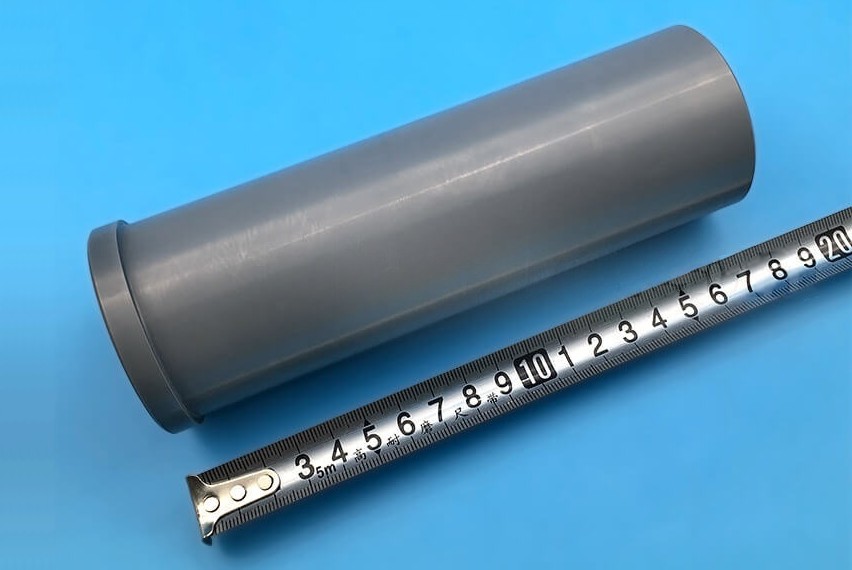

High temperature resistant silicon nitride ceramic tube

Alias: Thermal shock resistant ceramic protective sleeve / Refractory silicon nitride ceramic shaft sleeve

Description:

Precision ceramic products such as high-temperature resistant silicon nitride ceramic tubes and thermal shock-resistant ceramic protective sleeves have excellent performance in high-temperature and high-pressure environments, providing reliable solutions for various industrial and technological applications. With their excellent heat resistance, thermal shock resistance, chemical stability, and other characteristics, they play an important role in petrochemical, aerospace, energy, and other fields.

Features:

1. Heat resistance

High-temperature resistant silicon nitride ceramic tubes and thermal shock-resistant ceramic protective sleeves have excellent heat resistance and can maintain stable physical and chemical properties at extreme high temperatures, suitable for high-temperature furnaces, combustion devices, heat treatment equipment and other scenarios.

2. Thermal shock resistance

These precision ceramic products have excellent thermal shock resistance and can withstand rapid temperature changes without cracks or breakage, ensuring stable operation of equipment in thermal shock environments, such as temperature fluctuations in high-temperature processes.

3. Chemical stability

High-temperature resistant silicon nitride ceramic tubes and thermal shock-resistant ceramic protective sleeves have good chemical stability, excellent corrosion resistance to acid-alkali solutions, corrosive gases, etc., and can be used stably for a long time in harsh chemical environments.

4. Precision machining

These precision ceramic products can be customized for precision processing to meet the specific size, shape, pore size and other needs of customers, and are widely used in various high-demand industrial and technological fields, such as: petrochemical, aerospace, energy, etc.

Applications:

1. Petrochemical

In the petrochemical industry, high-temperature resistant silicon nitride ceramic tubes and thermal shock-resistant ceramic protective sleeves are widely used in high-temperature reactors, catalyst carriers, high-temperature pipelines and other equipment to ensure the stable operation of equipment in extreme working environments.

2. Aviation & Aerospace

In the aerospace field, these precision ceramic products are used as multiple key components of aviation equipment and devices, capable of withstanding high temperature and high pressure working conditions, ensuring the safety and reliability of aircraft devices.

3. Energy industry

In the energy field, high-temperature silicon nitride ceramic tubes and thermal shock resistant ceramic protective sleeves are used in burners, boilers, thermal power stations and other equipment in thermal power plants, and undertake key thermal insulation, protection, and thermal conductivity functions.

4. Laboratory scientific research

In the field of laboratory research, these precision ceramic products are used in high-temperature reactors, high-temperature furnaces, chemical experimental equipment, etc., providing a stable and reliable experimental environment and support.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.