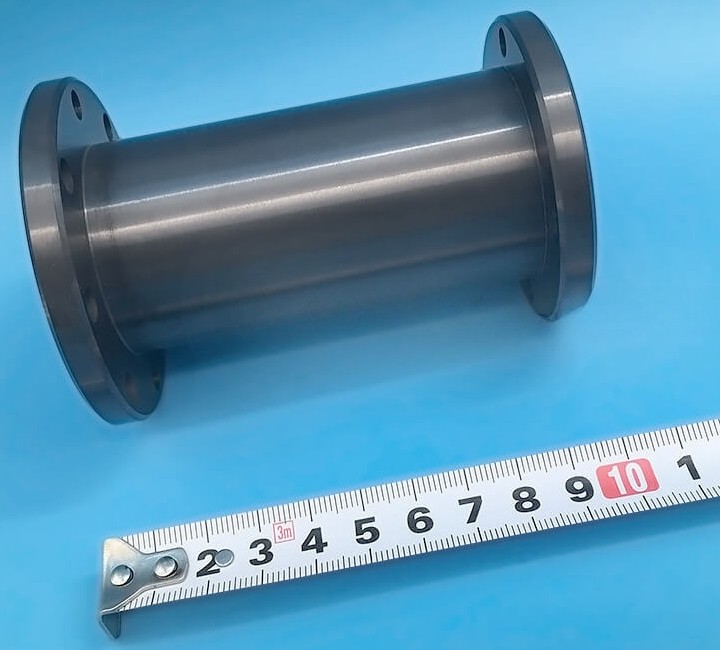

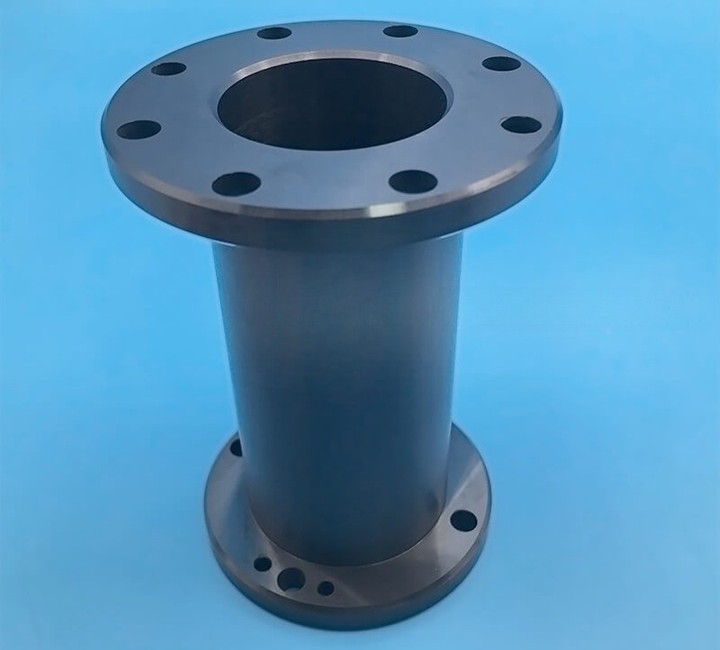

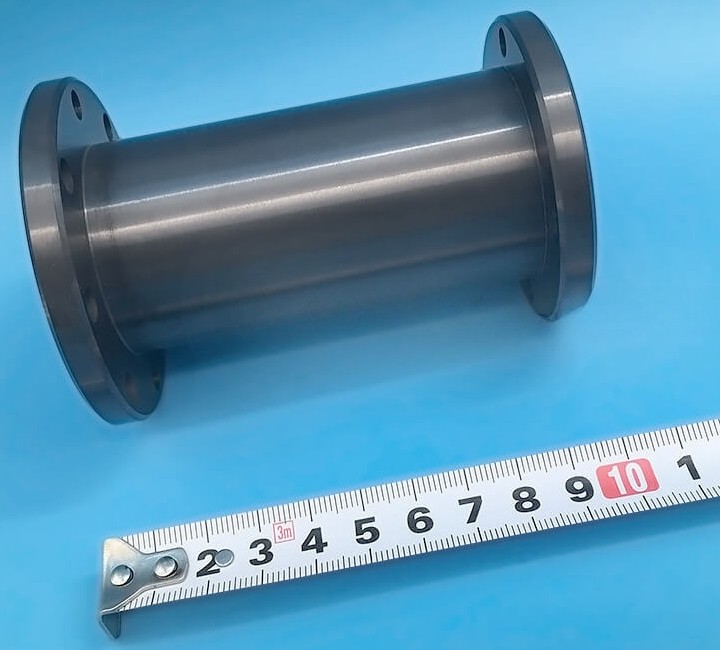

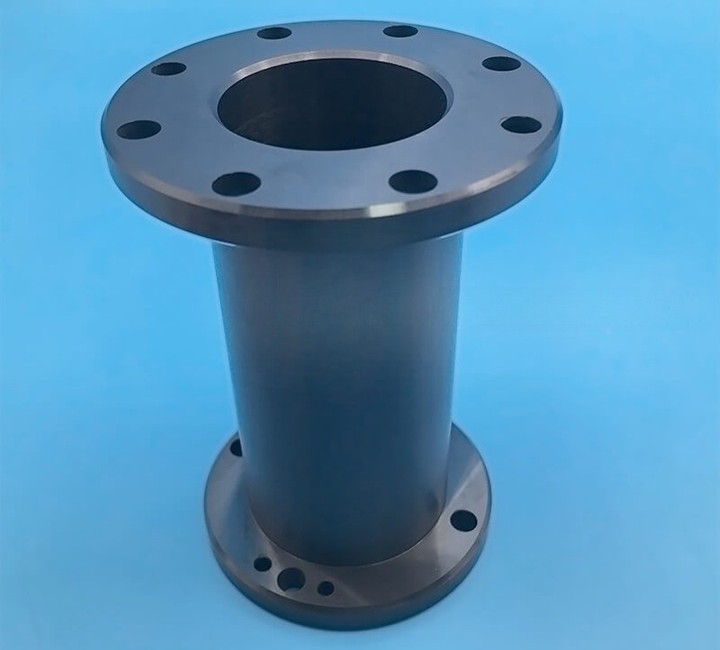

Silicon nitride ceramic pipe fittings / Flange short tube

Alias: High temperature resistant insulated ceramic protective tube

Description:

Ceramic pipe fittings made of silicon nitride (Si3N4) material, the design of which includes two flanges with multiple screw holes, such a design facilitates the installation of the pipe fittings into larger piping systems. These screw holes provide the multi-point fastening required for installation, ensuring the stability and safety of the pipe fittings under high-pressure or high-temperature operating conditions. Due to their excellent resistance to heat, abrasion and chemical corrosion, they are ideal for the manufacture of industrial pipe fittings for extreme conditions.

Features:

Silicon nitride ceramic pipe fittings, Alias: High temperature resistant insulated ceramic protective tube, exhibit multiple key design features and material advantages that enable them to excel in extreme conditions:

1. Structural design

The pipe fitting includes two flanges with multiple screw holes that facilitate the pipe fitting to be installed into larger piping systems. The multi-point fastening design ensures stability and safety under high-pressure or high-temperature operating conditions.

2. High-performance materials

Pipe fitting material silicon nitride ceramics have excellent heat, abrasion and chemical resistance, making them suitable for manufacturing industrial pipe fittings for extreme conditions. The low thermal expansion coefficient (3.1 × 10-6/℃) and high thermal conductivity (15-20 W/(m · K)), which helps maintain the structural integrity of pipe fittings during frequent thermal cycling.

3. Abrasion and impact resistance

With a Vickers hardness of up to 1500HV and a compressive strength of up to 2500MPa, silicon nitride provides excellent wear and impact resistance, enabling pipe fittings to resist wear and mechanical stress that may be encountered during operation.

Applications:

Silicon nitride ceramic pipe fittings that excel in multiple industrial applications:

1. Chemical treatment

In the chemical industry, these pipe fittings are used to transport highly corrosive chemicals. Their chemical resistance and high-temperature resistance ensure reliability and safety when dealing with acids, alkalis, and other aggressive substances.

2. Petroleum refining

In oil and gas refining, these pipe fittings are used in high-temperature and high-pressure environments, providing essential insulation and protection against material degradation and system failures.

3. Advanced material manufacturing

In the high-temperature material processing and advanced manufacturing industries, silicon nitride pipe fittings are used to protect critical components, such as in high-temperature furnaces and reactors, ensuring process stability and efficiency.

Silicon nitride ceramic pipe fittings, with their superior design and high-performance material properties, provide reliable solutions in high-temperature, high-pressure, and chemically aggressive environments. The optimized design and precision manufacturing of these pipe fittings ensure that they can maintain performance and stability in the most demanding industrial applications, enhancing the safety and efficiency of the entire system. Given their durability and functionality, silicon nitride ceramic pipe fittings have become indispensable components in fields such as chemical processing, petroleum refining, and advanced material manufacturing.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.