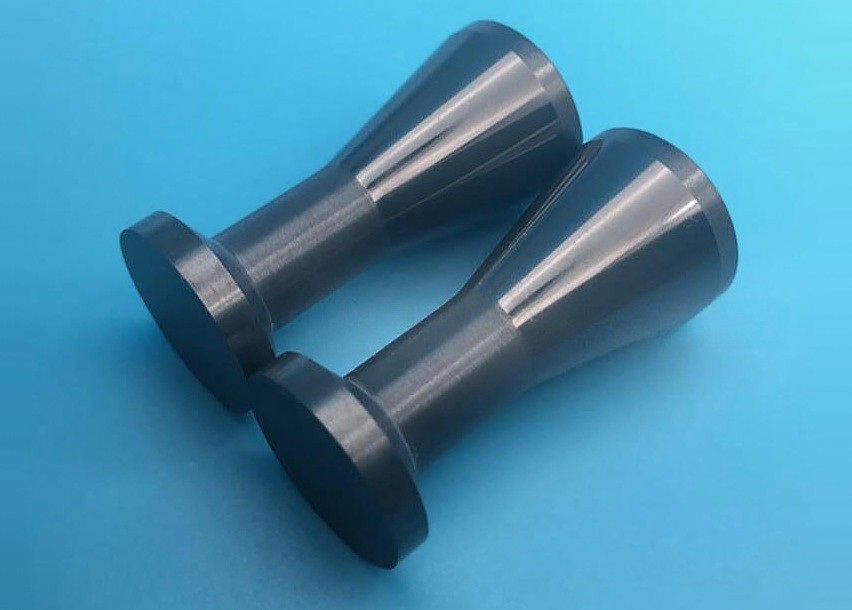

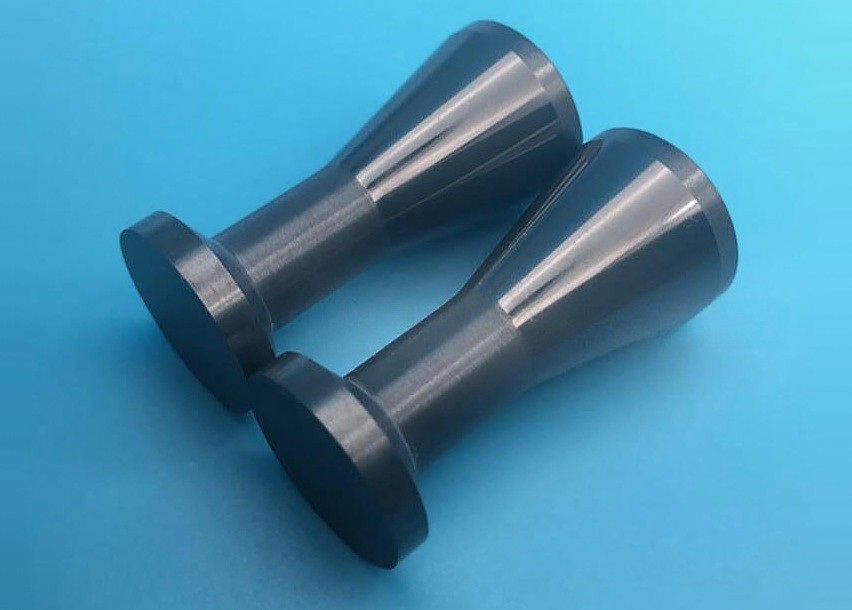

Silicon nitride ceramic plunger Alias: Insulated ceramic piston

Description:

Ceramic plungers made of silicon nitride (Si3N4) material, also known as insulating ceramic pistons. They are commonly used in high-performance pumps and valves, especially in applications that require corrosion and wear resistance, such as chemical processing, medical devices, food processing, and broader industrial applications. The material's low coefficient of thermal expansion and high thermal conductivity ensure dimensional stability and operational efficiency even in environments with drastic temperature changes.

Features:

Silicon nitride ceramic plungers, also known as insulated ceramic pistons, showcase the exceptional performance of silicon nitride ceramics as industrial-grade plunger/piston components:

1. Excellent mechanical strength and wear resistance

Silicon nitride has an elastic modulus of up to 290GPA and a Vickers hardness of 1500HV, which provide excellent wear and pressure resistance, allowing the plunger to maintain stability and long-term durability under high load conditions.

2. High heat resistance and thermal shock resistance

The maximum operating temperature is 1200℃, and the stability coefficient of thermal shock is as high as 500℃, which allows the plunger to maintain the stability of size and performance in environments with high temperature fluctuations.

3. Excellent chemical stability

The chemical inertness of silicon nitride allows it to excel in various corrosive environments, making it particularly suitable for applications such as chemical processing and medical devices.

4. Good sealing performance and low friction performance

The smooth outer surface and precise machining dimensions of the plunger help provide good sealing properties, reducing friction and wear during operation, thereby improving the efficiency of the overall system.

Applications:

Silicon nitride ceramic plungers are widely used in several demanding industrial settings, including:

1. Chemical treatment equipment

Used in pumps and valves that handle corrosive chemicals, the chemical stability and heat resistance of the plunger ensure the reliability and safety of the equipment.

2. Medical equipment

In medical devices where high-temperature sterilization and chemical sterilization are common, silicon nitride plungers are used to ensure safe and accurate device operation.

3. Food processing

Silicon nitride plungers are used in equipment in the food industry, leveraging their non-toxic and corrosion-resistant properties to ensure food safety and processing efficiency.

4. High-performance pumps and valves

In industrial pumps and valves that require extreme tightness and durability, the plunger's resistance to high temperatures and mechanical strength play a key role.

Silicon nitride ceramic plungers are indispensable industrial components in various extreme environments through their exceptional wear resistance, high-temperature resistance, chemical stability, and excellent insulation properties. These properties make them particularly important in applications with high temperatures, pressures, and the need for high cleanliness and precise control, such as chemical processing, medical equipment, and food processing. The high performance and reliability of silicon nitride plungers make them a superior alternative to traditional metal pistons, meeting the demands of modern industries for high-tech materials.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.