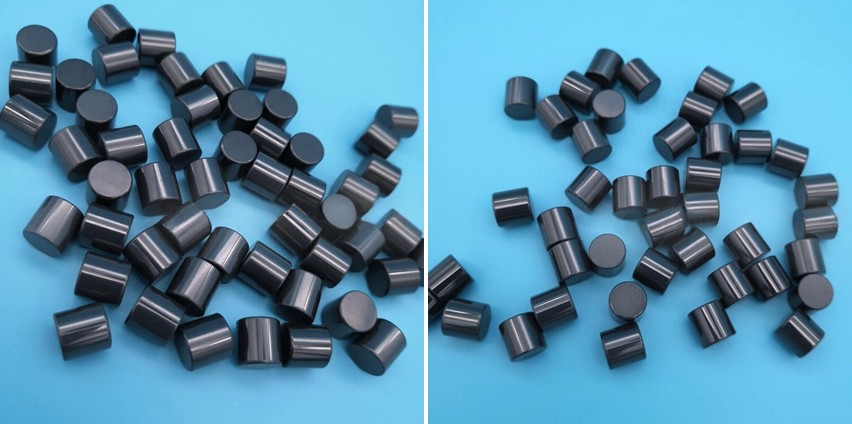

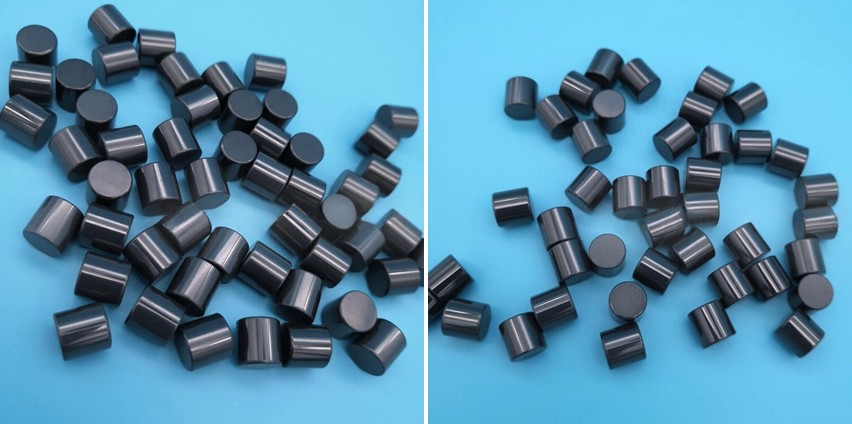

Silicon nitride ceramic bearing rollers

Alias: high-strength wear-resistant ceramic bearing cylindrical balls

Description:

Bearing rollers made of silicon nitride (Si3N4) ceramics, also known as high-strength wear-resistant ceramic bearing cylindrical balls. These bearing rollers are commonly used in high-precision and high-performance bearing systems, such as in aerospace & aerospace, automotive, electronic equipment and industrial machinery. By using silicon nitride ceramic rollers, you can significantly improve the durability and performance of bearings, reduced maintenance needs and extending the lifespan of your equipment.

Features:

Silicon nitride ceramic bearing rollers (Alias: high-strength wear-resistant ceramic bearing cylinder) demonstrate the excellent properties of silicon nitride as a high-performance material, suitable for applications requiring extreme durability and performance:

1. Excellent mechanical strength and wear resistance

Silicon nitride has a Vickers hardness of up to 1500HV and a flexural strength of 600MPa, which gives bearing rollers excellent wear and fracture resistance under high load conditions.

2. Excellent corrosion resistance and heat resistance

These bearing rollers are capable of withstanding maximum operating temperatures of up to 1200℃, making them suitable for high-temperature environments, while their chemical stability ensures longevity in corrosive environments.

3. Low density and high performance

With a density of only 3.2 g/cm³, silicon nitride helps reduce the overall structural weight compared to traditional metal materials, thereby improving the efficiency and speed of mechanical equipment.

4. Smooth surface treatment

The bearing roller finish is very smooth, effectively reducing friction, improving bearing operating efficiency, and significantly reducing heat generation, which is a crucial feature in high-speed operation.

Applications:

Silicon nitride ceramic bearing rollers excel in several high-end applications:

1. Aviation & Aerospace

In the aerospace sector, these bearing rollers are used in engines and other critical aviation components that need to withstand extreme temperature and pressure conditions.

2. Automotive industry

In the drivetrain of high-performance vehicles, silicon nitride bearing rollers reduce component weight, improving fuel efficiency and engine performance.

3. Electronic devices

In high-speed rotating electronic devices, such as hard disk drives and high-speed motors, the use of silicon nitride bearing rollers can improve operational efficiency and equipment life.

4. Industrial machinery

In high-load and high-speed industrial applications, such as textile machinery and production line equipment, these bearing rollers provide a solution for high efficiency and low maintenance requirements.

Silicon nitride ceramic bearing rollers are an ideal alternative to traditional metal rollers, especially in applications that require extreme performance and durability. Its unique material properties, such as high strength, wear resistance, corrosion resistance, and heat resistance, make it excellent in high-speed, high-load, and high-temperature environments. These bearing rollers significantly improve the efficiency and reliability of the overall system by reducing energy consumption and extending the service life of equipment, aligning with the pursuit and demand of high-performance materials in modern industry.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.