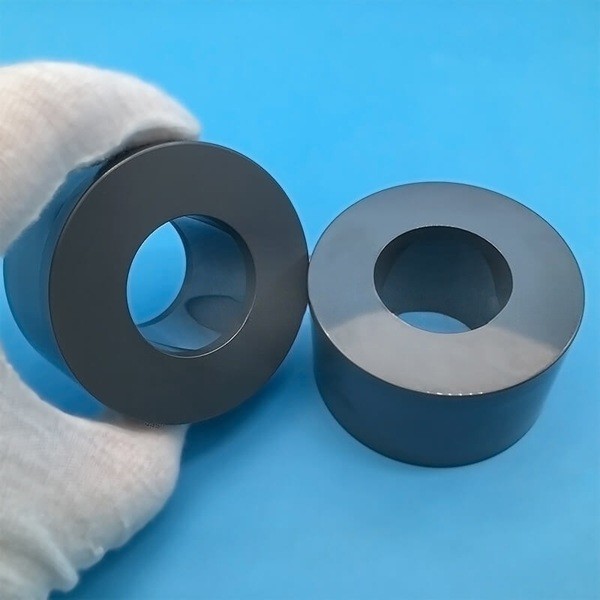

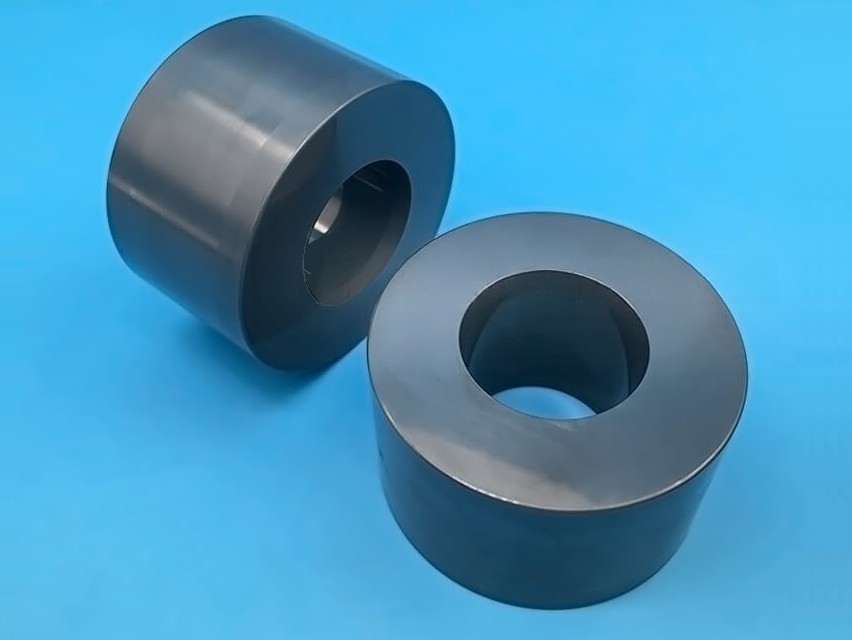

Silicon nitride ceramic roller ring/sleeve Alias: High-temperature insulated ceramic sealing ring

Description:

Roller ring/sleeves made of silicon nitride (Si3N4) ceramic, also known as high-temperature insulated ceramic sealing rings. The design of these ring sleeves allows them to perform critical rolling or sealing functions in various mechanical and industrial applications. For example, in bearing structures, these ring sleeves can be used as roller supports or as part of bearings, ensuring smooth movement and reducing friction. Its high-temperature insulation properties make it particularly suitable for use in equipment that requires thermal insulation or operates in high-temperature environments.

Features:

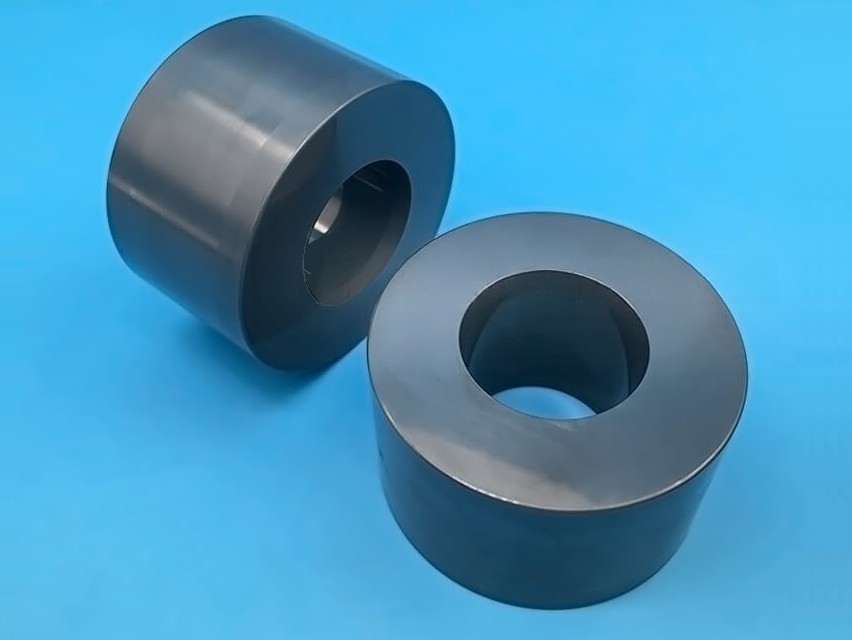

Silicon nitride ceramic roller ring sleeves, also known as high-temperature insulated ceramic seal rings, have several key design and material properties that make them excel in demanding industrial environments:

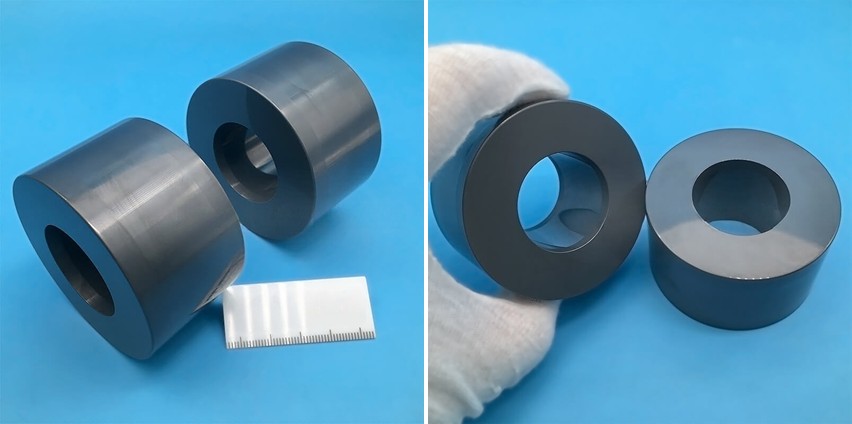

1. Precise size and shape

These ring sleeves are designed with precise inner and outer diameter dimensions, and the smooth surface helps reduce friction and wear, ensuring a precise fit and high performance in applications. This precision is achieved through advanced manufacturing techniques, guaranteeing consistency and compatibility during assembly and use.

2. High temperature insulation performance

The choice of material for the ring sleeve makes it particularly suitable for use in high-temperature environments, capable of withstanding operating temperatures up to 1200℃. In addition, the thermal conductivity of silicon nitride (15-20 W / (m · K)) and thermal shock stability coefficient (△T℃ is 500), so that these ring sleeves maintain stable performance in environments with large temperature changes.

3. Wear and chemical resistance

With a Vickers hardness of up to 1500 HV, silicon nitride provides excellent wear resistance, and its chemical stability allows it to be used in chemically aggressive environments such as chemical processing and petrochemical applications.

Applications:

Silicon nitride ceramic roller ring sleeves play a key role in multiple industrial applications, especially where high-temperature insulation and precision sealing are required:

1. Bearings and mechanical transmissions

In the bearing structure, these ring sleeves can be used as roller supports or as part of bearings, ensuring smooth mechanical movement and reducing wear, especially in high-speed or high-temperature operating conditions.

2. High temperature industrial equipment

In equipment that requires thermal insulation or operation in high-temperature environments, such as industrial furnaces and heat treatment equipment, silicon nitride ring sleeves provide the necessary thermal protection and structural integrity.

3. Aviation and Aerospace

In the aerospace sector, these ring sleeves are used in various engines and propulsion systems where their high-temperature stability and wear resistance are crucial for ensuring the reliability of critical components.

4. Chemical treatment

Due to their chemically resistant properties, these ring sleeves are used as sealing and insulating components during chemical processing, preventing the leakage of harmful chemicals.

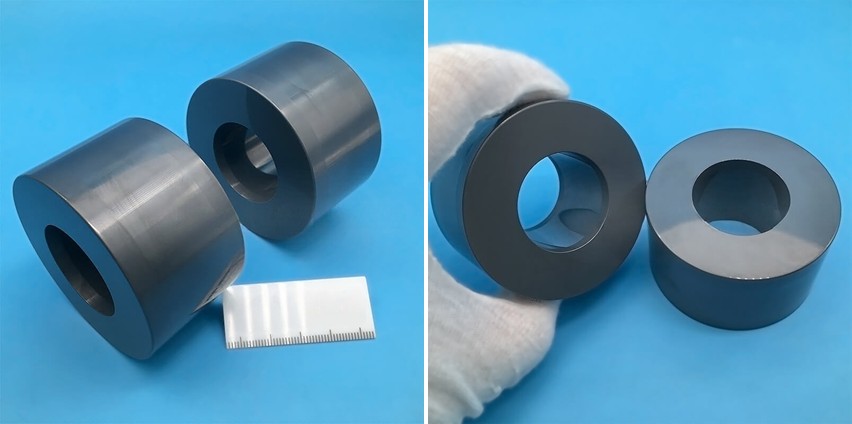

With its exceptional wear resistance, high-temperature stability, and chemical stability, silicon nitride ceramic roller ring sleeves provide a reliable solution in several demanding industrial applications. The design and material properties of these ring sleeves ensure their long-lasting durability and high performance in high-temperature, high-pressure, and corrosive environments. Combining these features, silicon nitride ring sleeves play a key role in improving the overall mechanical efficiency of the system and ensuring operational safety, making it an indispensable component in modern industrial technology.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.