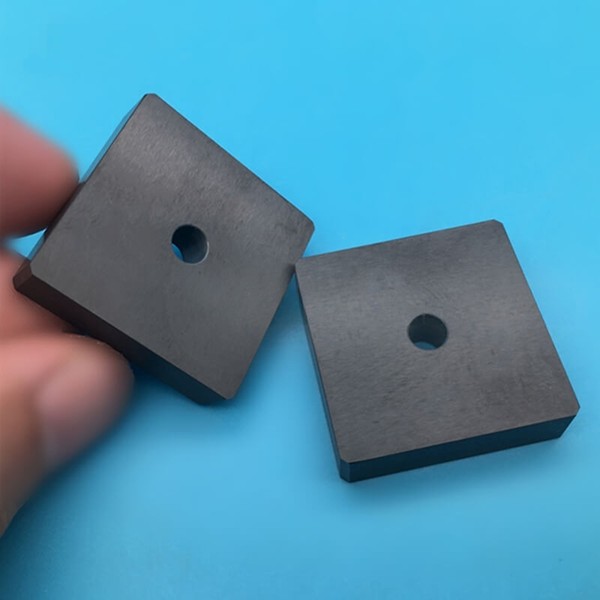

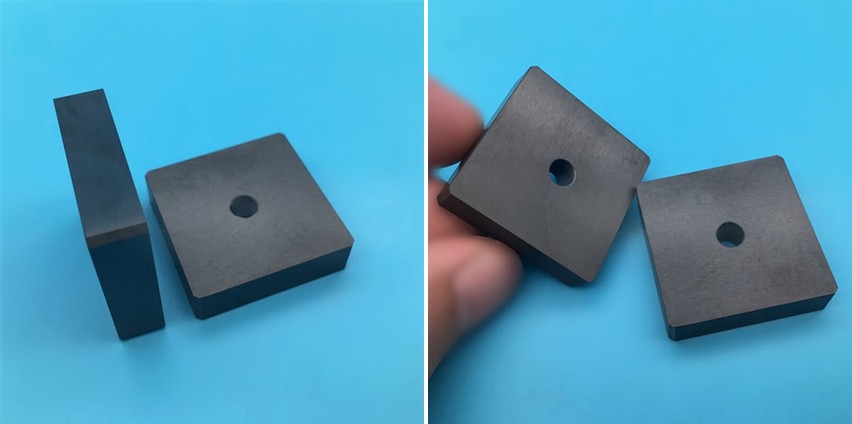

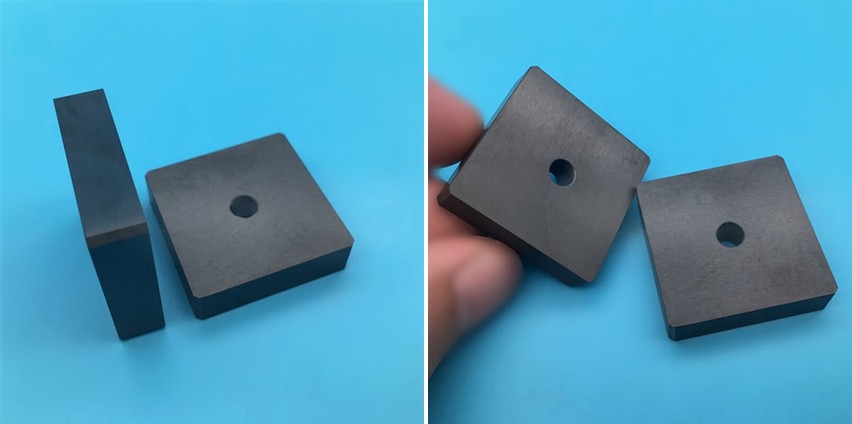

Silicon nitride ceramic blocks Alias: Industrial ceramic insulating block

Description:

Silicon nitride ceramic blocks, also known as industrial ceramic insulating blocks. Silicon nitride is a high-quality ceramic material with extremely high heat resistance and mechanical strength, commonly used for thermal insulation, insulation, and protection of components in high-temperature environments. These ceramic insulation blocks are commonly used in electronics manufacturing, high-temperature furnace interior components, chemical equipment, and other applications that require high insulation and thermal stability. They may be designed to include a center hole or other shapes to accommodate specific assembly requirements, adding versatility.

Features:

Silicon nitride ceramic block customization (Alias: Industrial ceramic insulating block) is designed for applications in extreme environments, especially those requiring high temperature resistance and superior insulation.

1. High temperature resistance and mechanical strength

Silicon nitride ceramics have a high-temperature tolerance of up to 1200℃, allowing them to maintain structural stability and functionality in a wide range of high-temperature applications. Additionally, its compressive strength is up to 2500 MPa, ensuring durability under high loads.

2. Excellent thermal management performance

With a thermal conductivity of 15-20 W / (m · K) and a very low coefficient of thermal expansion (3.1 x 10-6/℃), this material performs well during thermal cycling, adapting to rapid temperature changes without breakage.

3. Electrical insulation and chemical stability

It's extremely high electrical insulation strength and good chemical stability make it particularly important in electronics manufacturing and chemical processing environments where it can resist corrosion and maintain performance.

4. Custom design

Hole positions and shapes can be customized to specific application needs, such as center holes and other complex geometries, increasing assembly flexibility and versatility.

Applications:

1. Electronics manufacturing

Used as an insulating layer or support structure during high-temperature processing of semiconductor manufacturing and other electronic components, protecting sensitive components.

2. High temperature furnace

Used in the internal structure of high-temperature furnaces, such as brackets or thermal barriers, to improve the uniformity of the temperature inside the furnace and reduce energy loss.

3. Chemical equipment

Used in chemical reactors or treatment systems as insulating components resistant to corrosion and high temperatures.

4. Aerospace & Advanced Engineering Applications

In environments where extreme temperature resistance and mechanical strength are required, such as thermal protection systems for spacecraft or components for high-speed machinery.

Customized silicon nitride ceramic insulation blocks, with their superior heat resistance, mechanical strength, and insulation, offer unparalleled performance advantages in high-temperature, high-pressure, and corrosive environments. These ceramic blocks not only improve the operational efficiency and safety of the equipment, but also meet the precise needs of specific industrial applications through their highly customized design, greatly extending the service life and maintenance cycle of the equipment, and are indispensable high-performance components in modern industry.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.