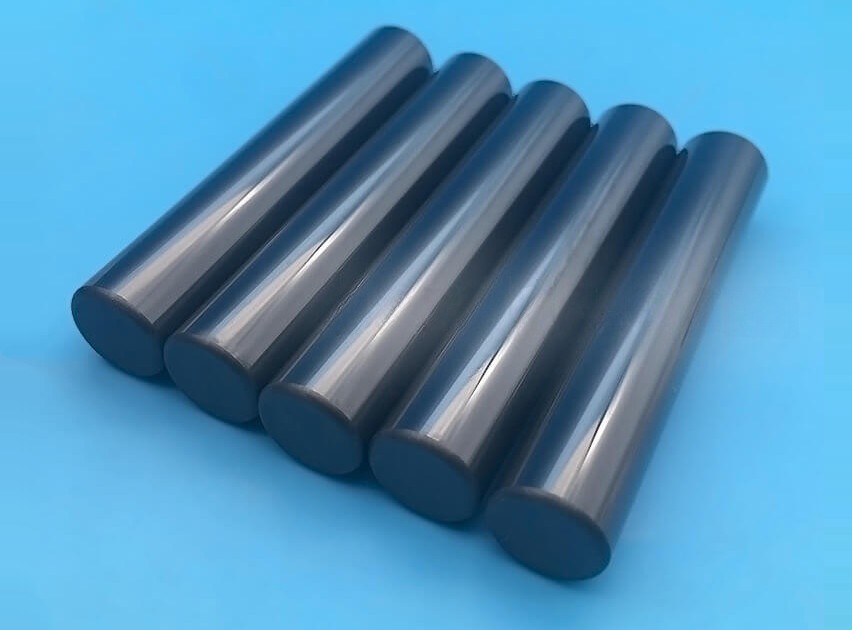

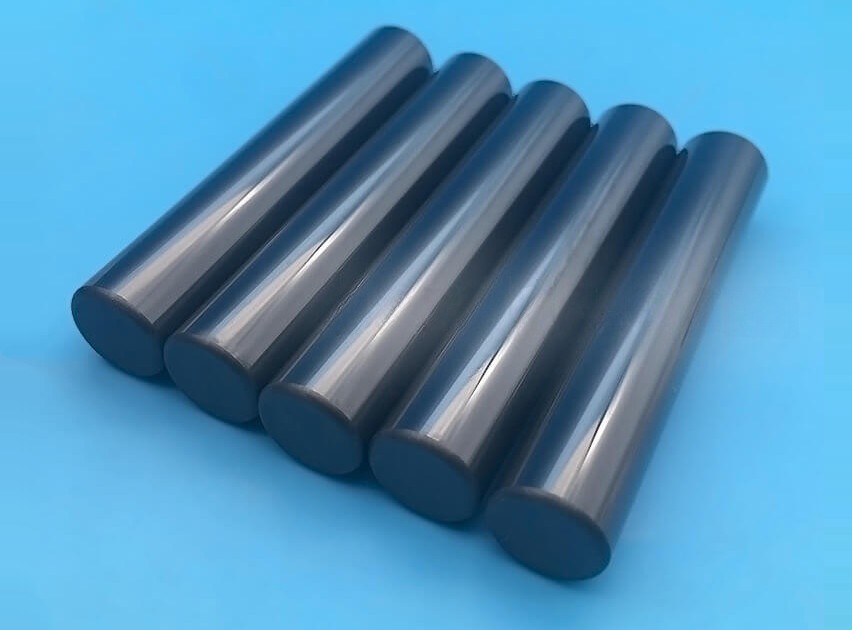

Silicon nitride ceramic rods

Alias: High temperature resistant silicon nitride ceramic shaft core/wear-resistant polished silicon nitride plunger

Description:

Precision ceramic products such as silicon nitride ceramic rods, ceramic shafts for high-temperature resistant oil pumps, and wear-resistant polished silicon nitride waterjet plungers play an important role in the industrial field. They have excellent heat resistance, wear resistance, chemical stability, etc., and are widely used in petrochemical, machinery manufacturing, aerospace and other fields.

Features:

1. Heat resistance

Silicon nitride ceramic rods, high-temperature resistant ceramic shafts for petroleum pumps, wear-resistant and polished silicon nitride waterjet plungers and other products have excellent heat resistance and can maintain stable physical and chemical properties in high-temperature environments, and are suitable for high-temperature processes and heat treatment equipment.

2. Abrasion resistance

These precision ceramic products have excellent wear resistance, are not easy to wear and tear in high-speed operation and high-pressure environments, and are suitable for the transportation and flow control of various liquids and gases, such as ultra-high pressure water pumps, valves and other equipment.

3. Chemical stability

Products such as silicon nitride ceramic rods, high-temperature resistant ceramic shaft cores for oil pumps, and wear-resistant and polished silicon nitride waterjet plungers have excellent chemical stability, can resist chemical corrosion such as acid and alkali solutions, corrosive media, and maintain long-term stable service performance.

4. Precision machining

These precision ceramic products can be customized for precision processing to meet customers' specific size, shape, surface finish, and other requirements, ensuring the accuracy and reliability of the equipment, such as the diameter accuracy of the pump shaft core and the surface finish of the waterjet plunger.

Applications:

1. Petrochemical

In the petrochemical industry, ceramic shafts for high-temperature resistant oil pumps are widely used in high-temperature and high-pressure oilfield drilling equipment, which can withstand harsh working environments and extend the service life of equipment.

2. Machinery manufacturing

In the field of machinery manufacturing, products such as silicon nitride ceramic rods and wear-resistant polishing silicon nitride waterjet plungers can be used in key components of high-precision machining equipment, such as CNC machine tools, grinders, etc., to improve processing accuracy and efficiency.

3. Aviation & Aerospace

In the aerospace field, these precision ceramic products are used in key components such as aero engines and aerospace devices in high-temperature and high-pressure environments to ensure the stable operation and safety of aviation devices.

4. High-pressure hydraulic engineering

In the field of high-pressure hydraulic engineering technology, wear-resistant polished silicon nitride waterjet plungers are widely used in high-pressure water cutting equipment, which can maintain stable working performance.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.