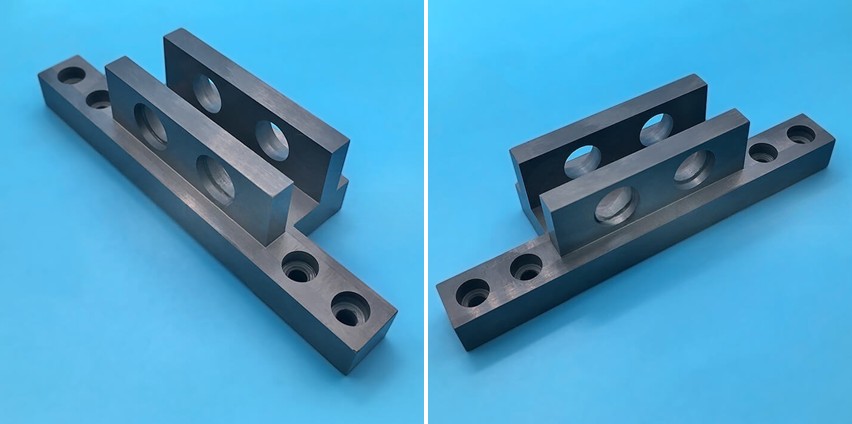

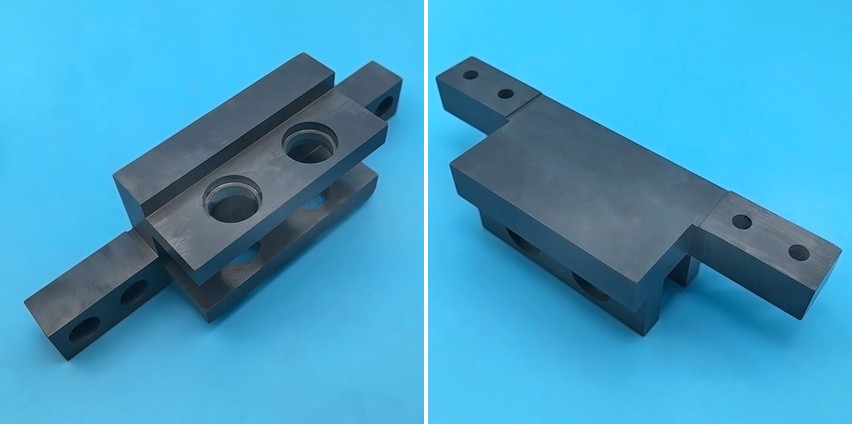

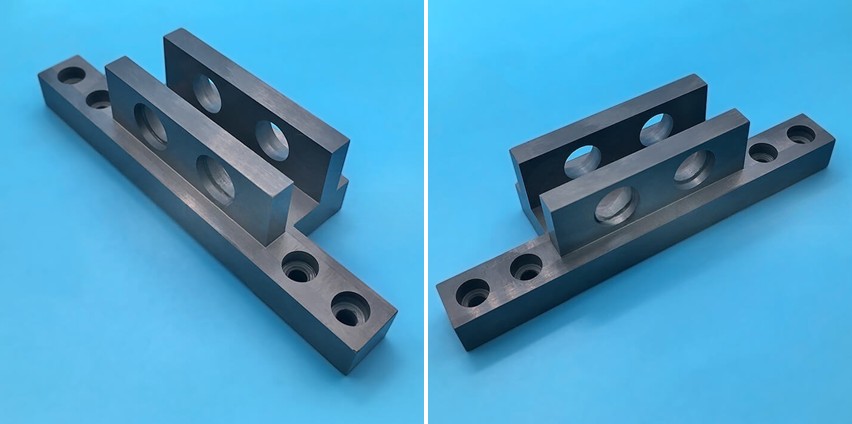

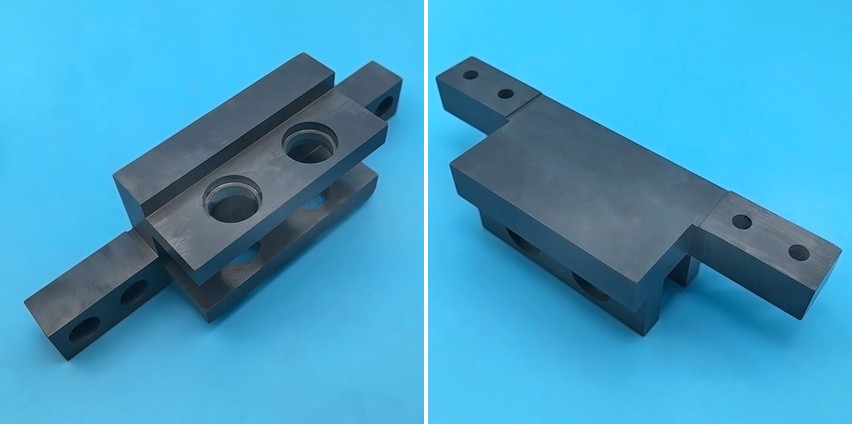

Silicon nitride precision ceramic structural parts

Alias: High temperature resistant ceramic wiring fixing base

Description:

A structural piece made of silicon nitride (Si3N4) precision ceramics, which is characterized by having multiple holes and precise geometries that are used to hold or serve as channels that allow fluids, gases, or wires to pass through, depending on their function in the system. The precise holes and shapes are designed to ensure a high degree of accuracy and compatibility in assembly and operation.

Features:

Silicon nitride precision ceramic structural parts, also known as High temperature resistant ceramic wiring fixing bases, demonstrate several key design advantages and material properties that make them excellent in high-performance engineering applications:

1. Precise hole and shape design

The features of the structural parts include multiple holes and precise geometries these holes can not only be used for fastening, but also as channels to allow fluids, gases, or wires to pass through. This design ensures a high level of accuracy and compatibility during assembly and operation, making it ideal for complex industrial applications.

2. Surface treatment

The surface of the structural parts is very smooth, which helps to reduce friction and wear, resulting in improved wear resistance and longer service life. The smooth surface also contributes to the overall efficiency and sealing performance of mechanical components.

3. Material Properties

The deep gray hue of silicon nitride not only showcases the material's high purity and uniformity but also reflects its physical properties enhanced by the high-temperature sintering process. Silicon nitride materials are known for their high strength, high temperature resistance (up to 1200℃), wear resistance, and chemical corrosion resistance.

Applications:

Silicon nitride precision ceramic structural parts are widely used in a number of demanding applications:

1. Aviation & Aerospace

In the aerospace industry, these structural components are critical components used in high-temperature, high-pressure environments, such as engines and thermal protection systems, ensuring the reliability and performance of equipment under extreme conditions.

2. Automotive industry

In the automotive industry, it is used in engine components and exhaust systems to improve combustion efficiency and reduce emissions.

3. Electronics and semiconductor manufacturing

Used in heat dissipation components and circuit mounts in electronic devices, providing high electrical insulation and thermal stability.

4. Industrial machinery

In heavy industry machines, it is used as a critical component to resist wear and chemical corrosion, enhancing the durability and efficiency of the machine.

Silicon nitride precision ceramic structural components provide critical support in several high-end industrial applications through their superior design and advanced material properties. The high precision and durability of these structural pieces make them particularly valuable in high-temperature, high-pressure, and corrosive environments. Combined with their excellent thermal stability and electrical insulation properties, silicon nitride structural components significantly enhance system reliability and efficiency, demonstrating the critical role of modern materials science in solving complex engineering challenges.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.