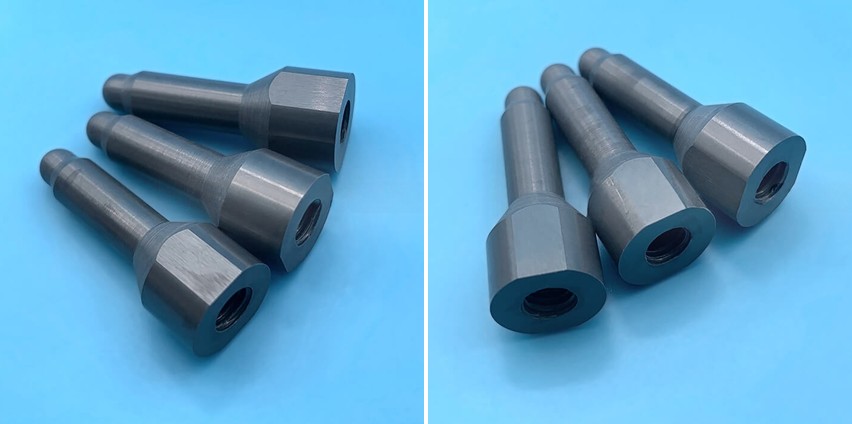

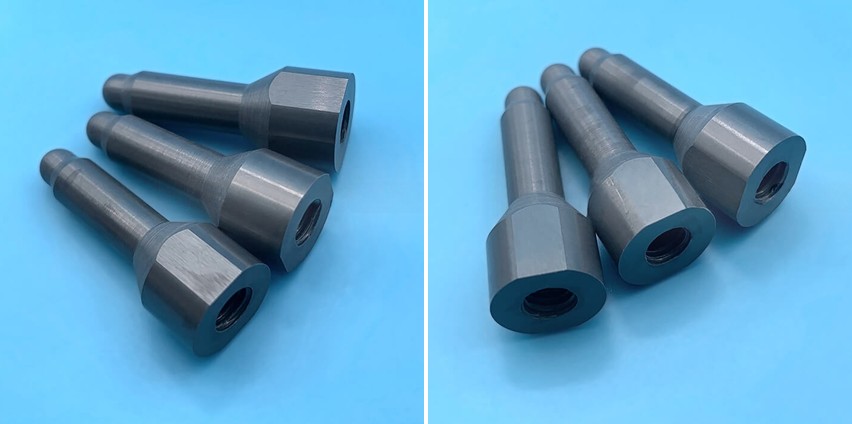

Silicon nitride ceramic locating pins Alias: spot-welding machine ceramic locating pin

Description:

The design of the dowel pin, which includes a cylindrical body and a spherical top, helps ensure precise positioning and support of the weld material in the spot-welding machine. The dark color on the surface of these dowels is typical of silicon nitride, which is made through a special sintering process to enhance their physical properties. The internal threaded design allows these locating pins to be easily installed into the corresponding mechanism.

Features:

Silicon nitride locating pin customization, also known as spot welding machine ceramic locating pin, is a key component designed for high-performance spot-welding machines, with the following notable design features:

1. Structural design

The locating pin has a cylindrical body and a spherical-head, this special shape design helps to precisely position and support the welding material in the spot-welding machine. The spherical top provides a better contact point, ensuring that the welded material is stable during machining.

2. Surface and color

The dark color exhibited by the locating pins, typical of silicon nitride, is made through a high-temperature sintering process that enhances its physical properties. In addition, the surface treatment also makes the locating pin show excellent wear resistance in high-temperature environments.

3. Internal thread design

The internal thread allows the locating pin to be easily installed into a spot welder or other corresponding mechanism, providing easy replacement and maintenance capabilities.

4. Material Properties

Silicon nitride offers extremely high mechanical strength (modulus of elasticity of 290 GPA) and excellent high temperature resistance (up to 1200℃), making it suitable for demanding industrial environments. Its Vickers hardness is up to 1500 HV and its compressive strength is 2500 MPa, ensuring stability and durability under high loads and temperatures.

Applications:

Silicon nitride locating pins have a wide range of uses in a variety of industrial applications, especially where high precision and durability are required:

1. Spot-welding machine application

In spot welding machines, these locating pins are used to precisely position metal materials, ensuring accuracy and repeatability in the welding process. Its resistance to high temperatures and wear makes it ideal for continuous high-intensity work.

2. High-temperature treatment environment

Due to the high thermal stability and mechanical strength of silicon nitride, locating pins are also suitable for other high-temperature processing environments, such as heat treatment and in-furnace operations.

3. Chemical processing

The chemical stability of silicon nitride allows locating pins to be used in chemical processing equipment, especially when dealing with more aggressive chemicals.

Silicon nitride locating pins offer reliable performance in high-temperature, high-stress industrial applications through their superior design and superior material properties. The meticulous design of its structure, its high-temperature resistance and mechanical stability together ensure long-term durability and high performance in extreme working environments. These features make silicon nitride locating pins the preferred component for high-performance spot welding and other precision manufacturing applications, demonstrating the high adaptability and value of modern materials science in practical applications.

Product customization:

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.