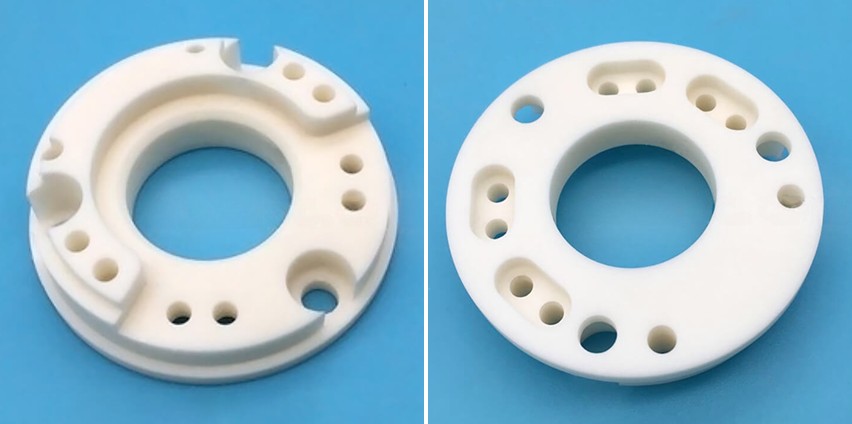

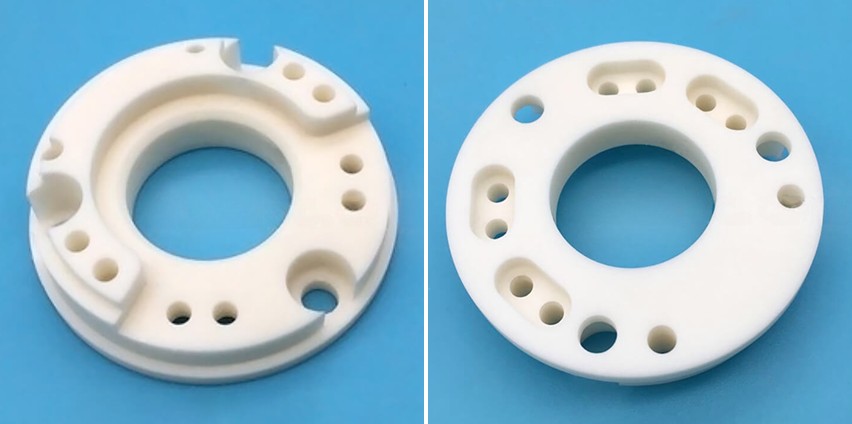

Alumina ceramic special-shaped structural parts Alias: Round porous ceramic base

Description:

Alumina (Al2O3) ceramic special-shaped structural parts, also known as round porous ceramic bases. These ceramic profiled structural parts are usually designed for specific applications where the porous structure can be used to fix, connect or serve as a support platform for sensors and electronic components. The designed holes and grooves not only provide mechanical fixation capabilities but also facilitate heat dissipation, gas or liquid pathways, making them widely used in automated machinery, electronic devices, and precision instruments.

Features:

Alumina ceramic special-shaped structural parts, also known as porous ceramic bases, are made of high-performance alumina (Al2O3) material and offer the following notable properties:

— High hardness and excellent wear resistance

Alumina ceramics have a Vickers hardness of up to 15.7 GPA, giving them excellent durability in high-wear environments.

— Good thermal stability and electrical insulation

The maximum operating temperature can reach 1650℃, and the breakdown strength exceeds 10 KV/mm, making it suitable for use at high temperatures and when electrical insulation is required.

— Design and manufacturing capabilities for complex structures

Structural parts of complex shapes and sizes can be manufactured according to the customer's specific application needs, such as support platforms or mounts with porous holes.

— Optimized Thermal and Fluid Management

The porous design not only provides retention but also aids in heat dissipation and efficient management of fluids and gases.

— High mechanical strength and compressive resistance

With a flexural strength of up to 330 MPa and a compressive strength of 2000 MPa, it guarantees stability and long-term durability of ceramic structural parts under physical loads.

Applications:

Alumina ceramic special-shaped structural parts are widely used in many high-tech fields:

1. Automated machinery

It serves as a connection or support component in robotic arms or robotic joints, providing the necessary mechanical strength and precision.

2. Electronic devices

It serves as a support or mounting platform for electronic components, providing electrical insulation and thermal management solutions.

3. Precision instruments

It is used as a precision component in scientific instruments and medical equipment, such as sensor holders or mounts, to ensure the stable operation of instruments.

4. Chemical treatment and environmental technology

Used in chemical reactors or filtration systems, subjected to high temperatures and corrosive media.

Alumina ceramic special-shaped structural parts play an important role in modern industry and technology due to their high-performance characteristics and structural design flexibility. These ceramic structural parts not only meet the industrial needs of high strength, high temperature resistance, and high precision, but also optimize thermal and fluid management through their porous structure design, significantly improving equipment performance and reliability. Through precision manufacturing techniques, these structural components are able to meet the needs of the most demanding applications, providing effective support and protection solutions for a wide range of high-end applications.

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.