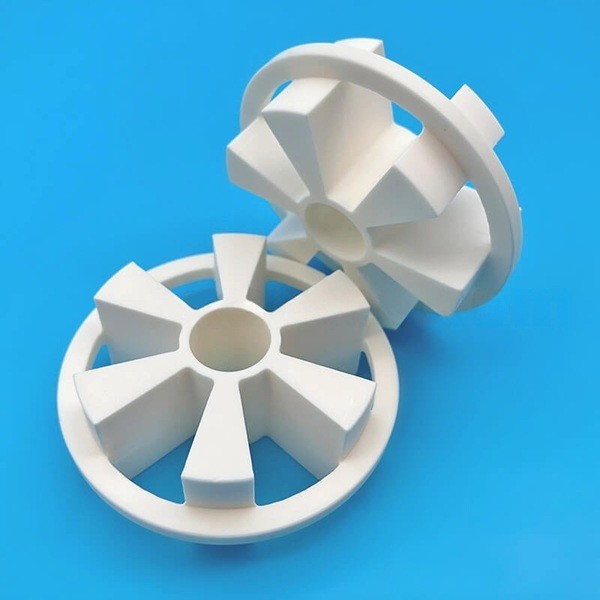

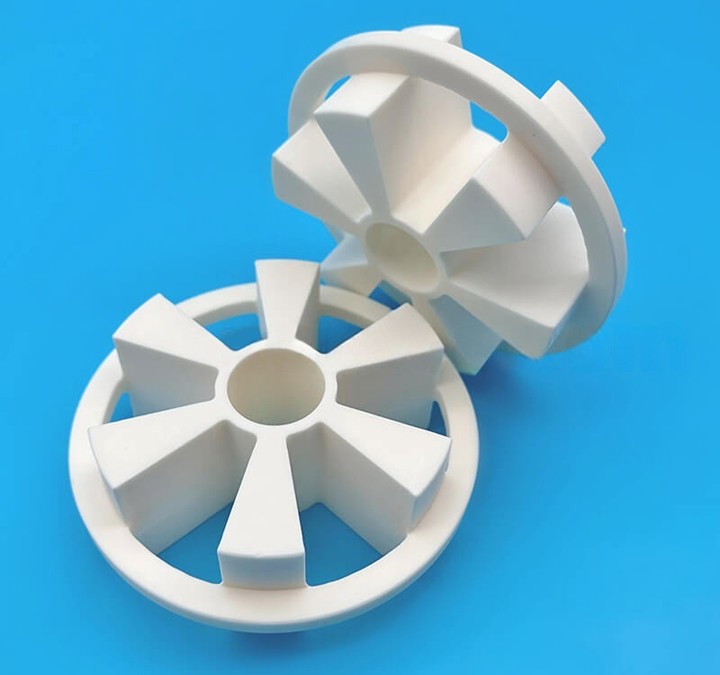

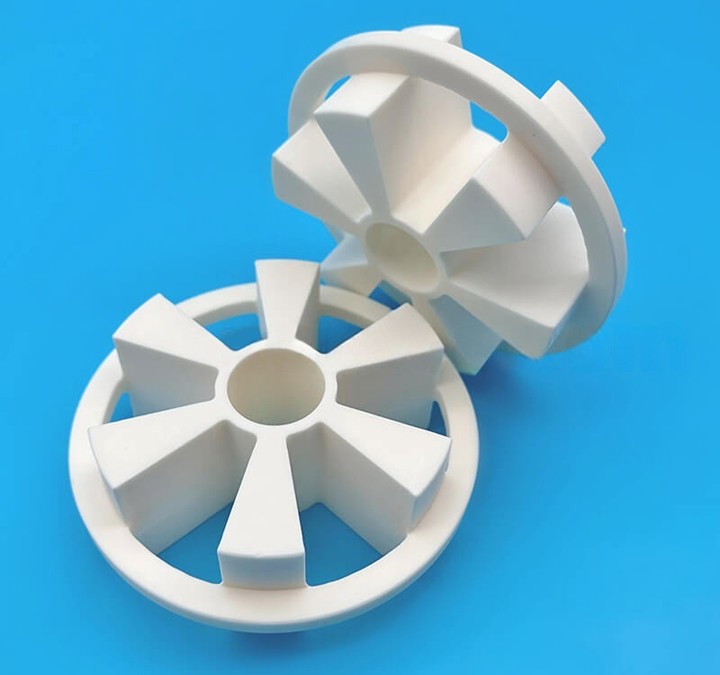

Alumina ceramic impeller Alias: High-speed rotating ceramic impeller components

Description:

Alumina ceramic impellers are high-performance rotating components made of high-purity alumina (Al2O3) as the base material, through isostatic pressing, dry pressing or injection molding processes, and then sintered at high temperatures. It has excellent wear resistance, corrosion resistance, high strength and insulation properties, and is an ideal choice for replacing metal or plastic impellers, and is widely used in pump body systems with wear resistance, corrosion resistance, high speed, and high cleanliness requirements.

Features:

1. Super abrasion resistance

Alumina ceramics have a hardness of up to 9 on the Mohs scale, which is much higher than stainless steel and engineering plastics, making them particularly suitable for pump systems with solid particles or strong friction media.

2. Excellent corrosion resistance

It has excellent chemical stability for most acid, alkali and salt media, and is especially suitable for strong corrosive fluid conditions, such as acid and alkali liquid transfer pumps.

3. High strength and rigidity

Even in high-speed or high-pressure pumps, it remains structurally stable, impact-resistant, and long-lasting.

4. Good insulation

Ceramics themselves are insulators and are suitable for electrochemical or special working conditions where conductivity is required.

5. High Temperature Resistance

The operating temperature can reach 1600℃, suitable for applications such as high-temperature hot water pumps, thermal medium circulation systems, etc.

6. Structure Customizable

Complex geometric structures can be customized according to customer drawings, such as: radial-vane, backward-curved, enclosed, open, semi-open and other different forms. Including boiler feed pumps and reverse osmosis high-pressure pumps with radial-vane impellers, HVAC circulation pumps and industrial process pumps with backward-curved impellers, etc., liquid transfer pumps and clean pumps in the pharmaceutical industry with enclosed impellers, pulp pumps and mine slag discharge pumps with open impellers, etc., chemical process pumps and medium pumps with fine particles with semi-open impellers, etc.

Applications:

1. Chemical pump industry

It is suitable as a core component of corrosion-resistant transfer pumps, circulation pumps, metering pumps, etc.

2. Environment-protection water treatment equipment

It is used for sewage treatment pumps, water purifier circulation pumps, etc., which is conducive to improving the service life of the pump.

3. Electroplating and electrolysis equipment

It is suitable for liquid transportation under strong acid and alkali resistance conditions, which can ensure the stable operation of the system.

4. Semiconductor / Optoelectronic Industry

In ultra-clean conveyor systems, it is suitable for the circulation of chemical liquids in dust-free clean rooms.

5. Pharmaceutical and food industry

It can be used in pump systems with strict hygiene requirements.

6. New energy systems

It is a circulation pump component in hydrogen energy, water electrolysis, and fuel cells.

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.