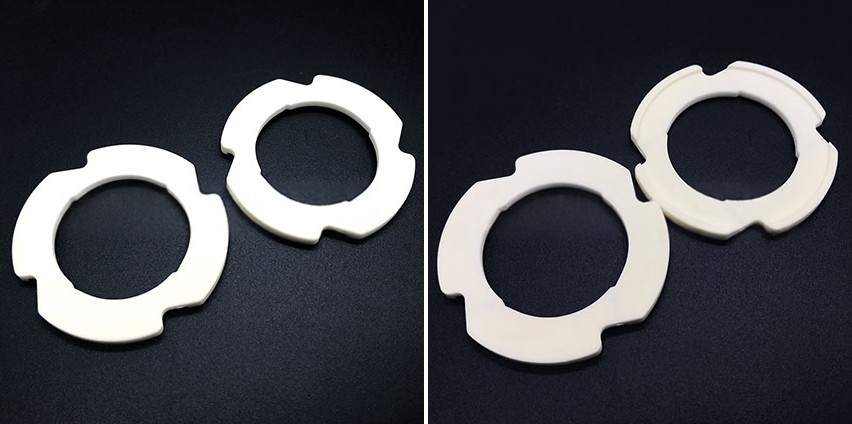

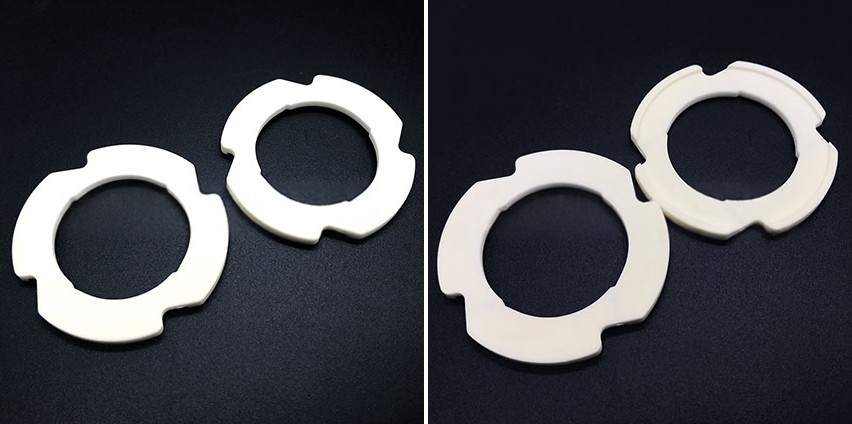

Alumina ceramic locating rings Alias: alumina ceramic ring parts

Description:

Customized alumina (Al2O3) ceramic locating rings, also known as ceramic rings. These ceramic rings feature multiple precision-machined positioning bayonets for precise positioning and fixation of components in the device. The high hardness and strength of alumina ceramics allow these rings to maintain their shape and performance even under high pressure and friction conditions, ensuring stable operation and long life of equipment.

Features:

Alumina ceramic locating rings, also known as ceramic ring parts, are critical components in the design of industrial equipment and precision machinery that require high precision and durability.

— Precision-machined bayonet with unique shape

These ring components feature precision-machined multiple bayonets and specific shape designs for precise positioning and fixation in equipment.

— High hardness and high strength

The high hardness (Vickers hardness up to 15.7 GPA) and high strength (compressive strength up to 2000 MPa) of alumina ceramics ensure that they maintain their shape and function under high pressure and friction environments, enhancing long-term stability and durability.

— Excellent corrosion resistance

Its excellent chemical stability makes it resistant to various chemicals, especially in high-temperature environments, avoiding material corrosion and degradation.

— Electrical insulation and high temperature resistance

Good electrical insulation properties and high-temperature stability make these ring components safe for use in high-voltage and high-temperature industrial applications.

Applications:

Alumina ceramic locating rings have a wide range of applications in several industrial sectors:

1. Industrial Equipment & Machinery

Used in industrial pumps, valves, or other fluid power equipment that require precise fluid control and fixation.

2. Electronics & Electrical Industry

Used in electrical equipment as an electrically insulating component to protect circuits from high temperatures and voltages.

3. Automotive and aviation industry

In automotive engine components and aerospace components, they are used in environments subjected to high temperatures and chemical corrosion, providing sealing and structural support.

4. Laser cutting and processing

Used in laser cutting machinery to precisely position and protect the cutting surface from mechanical damage.

5. High temperature environment applications

It is suitable for the chemical and metalworking industries that require high temperature resistance and chemical stability.

Due to its exceptional mechanical strength, wear resistance, and corrosion resistance, as well as excellent electrical insulation and high-temperature resistance, alumina ceramic locating rings provide reliable performance in a variety of industrial environments, especially in high-end applications that require extreme durability and precision. These properties make alumina ceramic ring parts indispensable in modern industrial technology applications.

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.