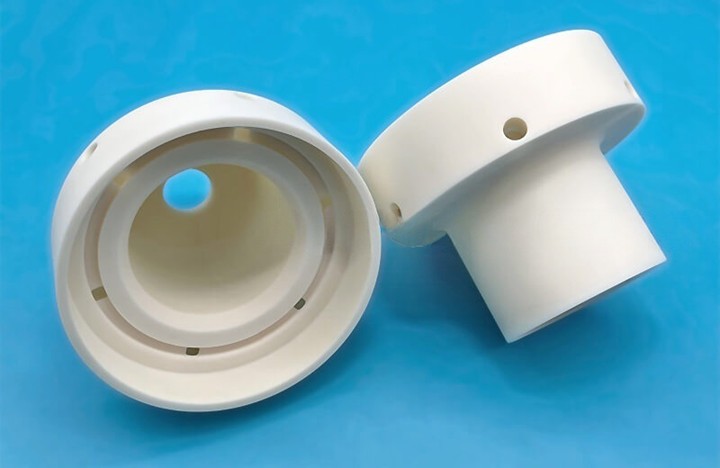

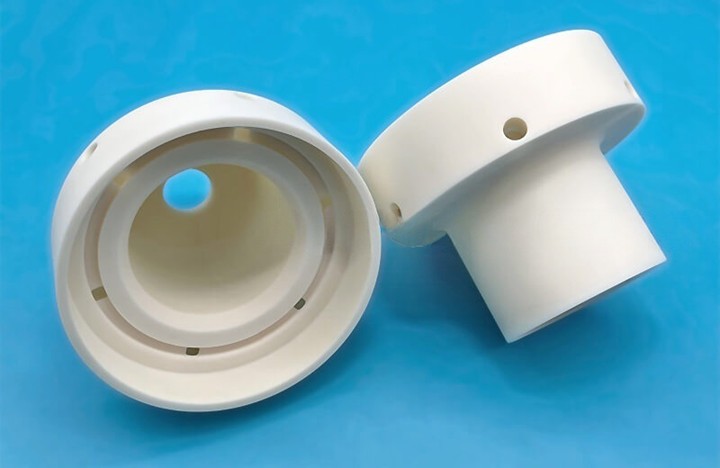

T-shaped Alumina Ceramic Cap Alias: Ceramic caps structural parts or insulated ceramic hats

Description:

T-type alumina ceramic cap is a high-performance component that combines Al2O3 material and precision engineering. It not only meets the needs of modern industries for high temperature resistance, corrosion resistance, and electrical insulation performance, but also provides reliability and stability in extreme environments through its customized design.

Features:

The design of the T-shaped alumina ceramic cap takes into account the harsh conditions of its application environment.

Firstly, its material choice, high-purity alumina ceramic, guarantees excellent mechanical strength and wear resistance. This material is not only highly thermally stable and able to withstand high-temperature environments for long periods of time, but its chemical resistance also makes it particularly important when dealing with harmful chemicals.

Secondly, the T-shaped design not only enhances the overall stability of the structure but also optimizes the assembly accuracy and ease of components. The internal structure of ceramic caps is specifically tailored to specific mechanical accessories or processes, ensuring seamless docking with equipment.

In addition, the surface treatment technology of alumina ceramics is also an important aspect of its design. The surface is specially processed to achieve a high level of smoothness, effectively reducing the risk of material adhesion or contamination, which is especially critical in the semiconductor and precision electronics industries.

Applications:

T-type alumina ceramic caps, mainly used in fields that require high thermal and electrical insulation properties. For example, in semiconductor manufacturing, this ceramic cap can serve as an internal furnace component, protecting sensitive semiconductor materials from heat damage.

In other high-tech electronic devices, such as laser equipment or high-frequency power supplies, alumina ceramic caps also play a crucial role in thermal insulation and protection.

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.