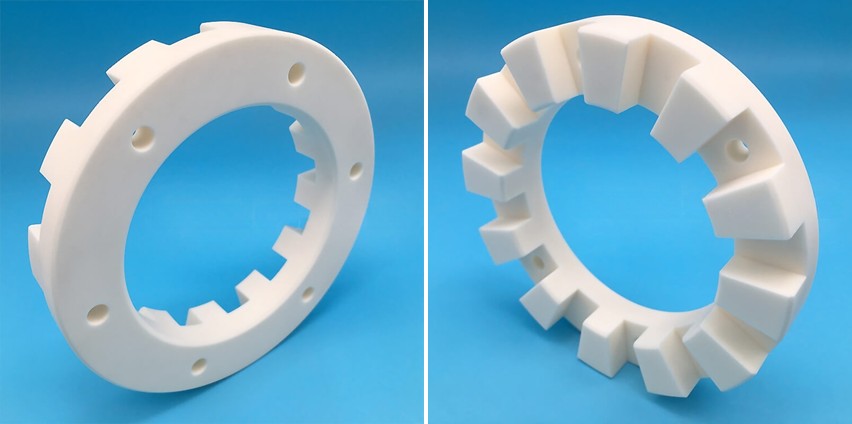

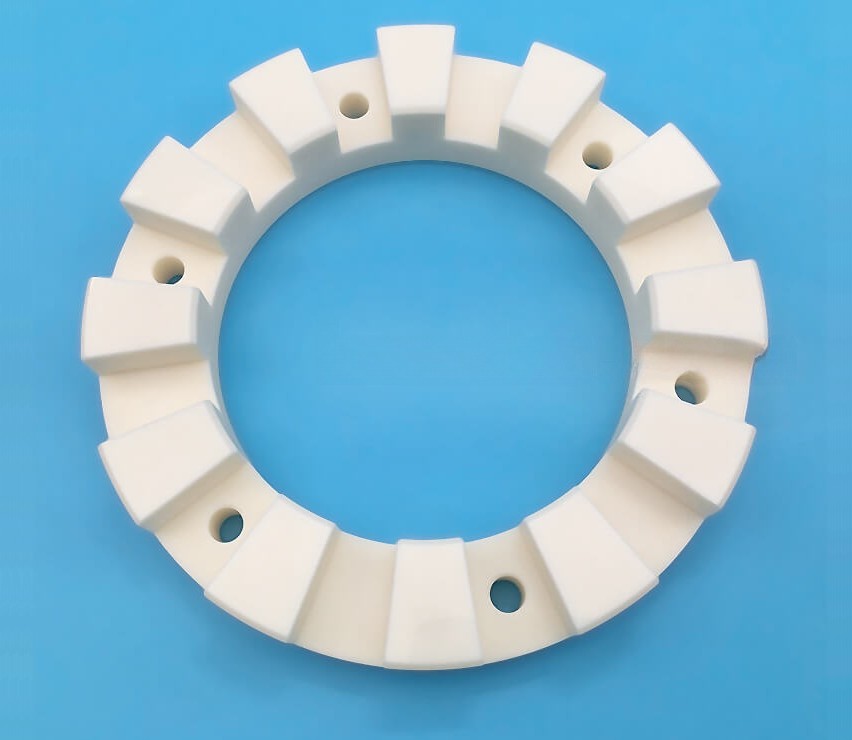

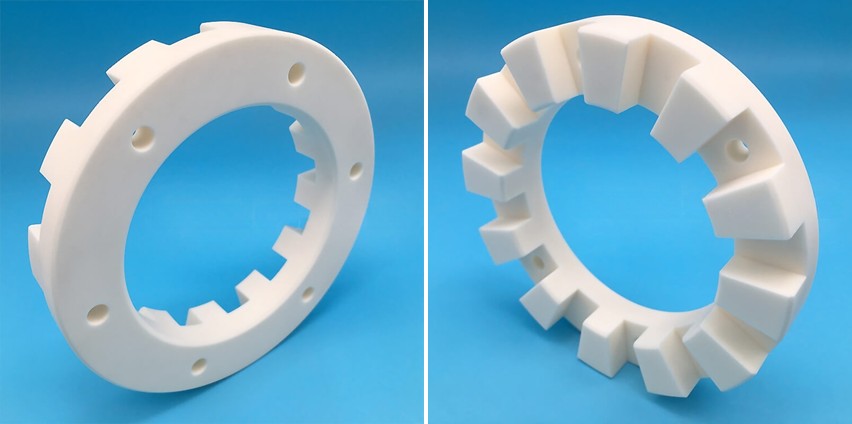

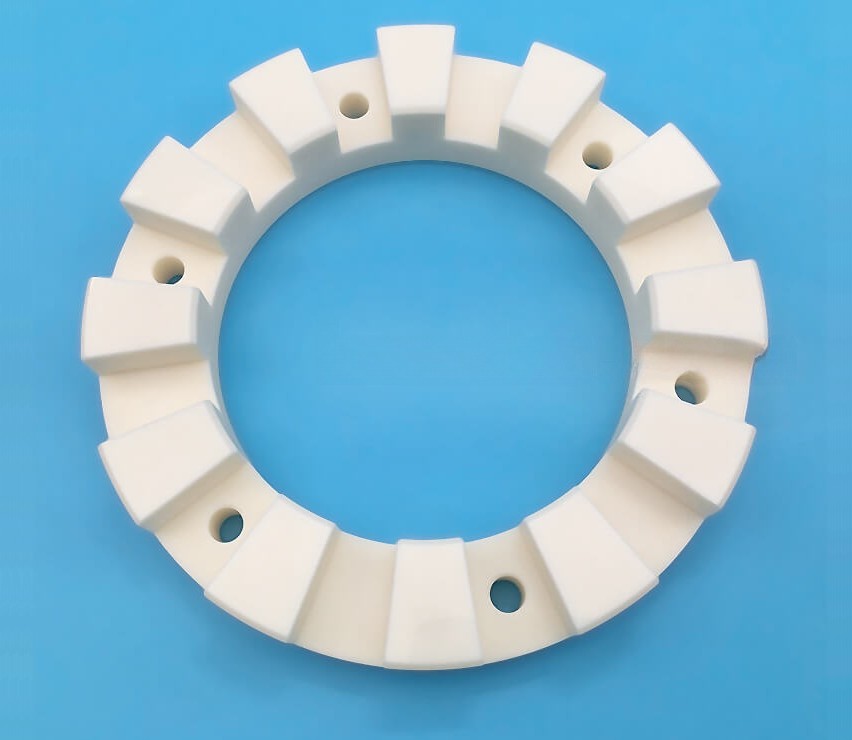

Alumina ceramic grading wheel Alias: Circular ceramic fixed seat or special ring

Description:

Customized alumina (Al2O3) ceramic grading wheels, also known as circular ceramic fixed seat or special rings. These ceramic grading wheels feature a unique groove design for precise sorting and separation of materials. The high hardness and strength of alumina ceramics allow these grading wheels to maintain their shape and performance even under high pressure and high friction conditions, ensuring stable operation and long life of the equipment.

Features:

Alumina ceramic grading wheels (Alias: circular ceramic fixed seat or special ring), a critical component designed for high-precision machinery and industrial equipment, are known for their exceptional mechanical properties, wear resistance, and corrosion resistance.

— Unique groove design

The unique groove design of the grading wheel allows for precise sorting and separation of materials as they pass, optimizing process flow and efficiency.

— High hardness and strength

The high hardness (Vickers hardness of 15.7 GPA) and high strength (compressive strength of 2000 MPa) of alumina ceramics ensure that the grading wheel maintains its shape and performance stability under high pressure and high friction conditions.

— Superior corrosion resistance

When dealing with chemicals and high-temperature environments, the corrosion resistance of alumina ceramics avoids corrosion and degradation of the material, extending its lifespan.

— Good electrical insulation and high temperature stability

Excellent electrical insulation properties and high temperature stability (up to 1650℃) make these graders suitable for a wide range of high-temperature industrial applications.

Applications:

1. Industrial equipment

Used in high-precision material handling and grading systems, such as powder metallurgy, mineral processing, etc.

2. Mechanical equipment

Used as a fixed seat for machinery, ensuring precise positioning and stability of mechanical components.

3. High temperature application

Reliable material handling and grading capabilities are provided in environments where high temperature resistance, such as heat treatment equipment and baking systems, is required.

4. Chemical and pharmaceutical industries

It is used to precisely control the separation and handling of chemicals, ensuring precise and safe processes.

Alumina ceramic grading wheels play a pivotal role in modern industrial applications, especially in material handling and sorting systems, through their advanced performance and custom design. Its durability and precise control capabilities provide a reliable solution for various applications, meeting the stringent requirements of industrial technology for high-performance materials.

In the field of precision ceramic processing and customization, Fudong Machinery is committed to the production of various high-performance ceramic parts, including zirconia ceramics, silicon nitride, aluminum nitride and other products. These ceramic parts have excellent thermal stability, electrical insulation, high temperature stability and wear resistance, and are widely used in key fields such as aerospace, electronics, machinery, military industry, and automotive.

With its excellent performance and reliability, our products provide customers with key support and guarantees, helping them improve production efficiency and optimize product performance.