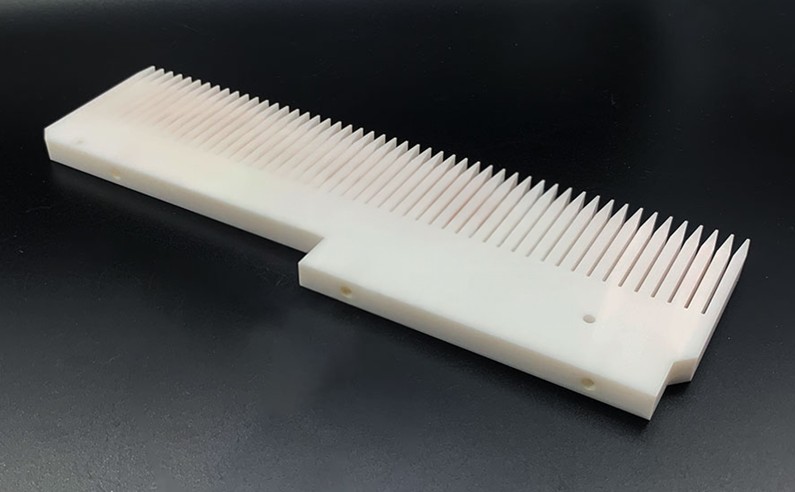

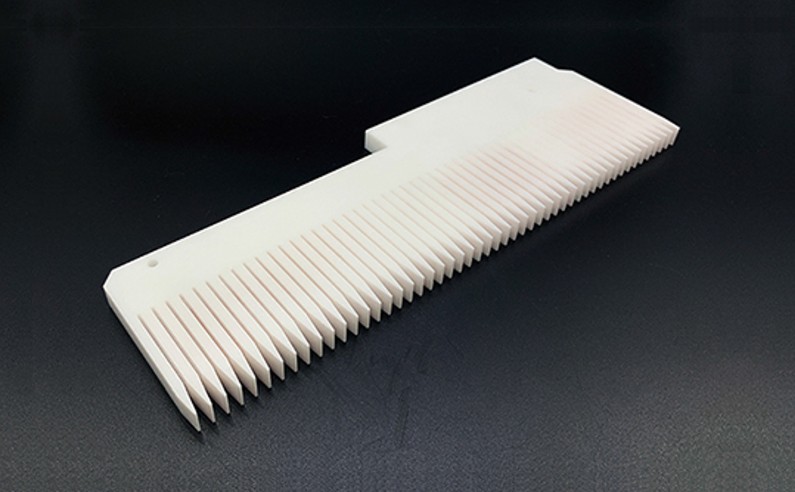

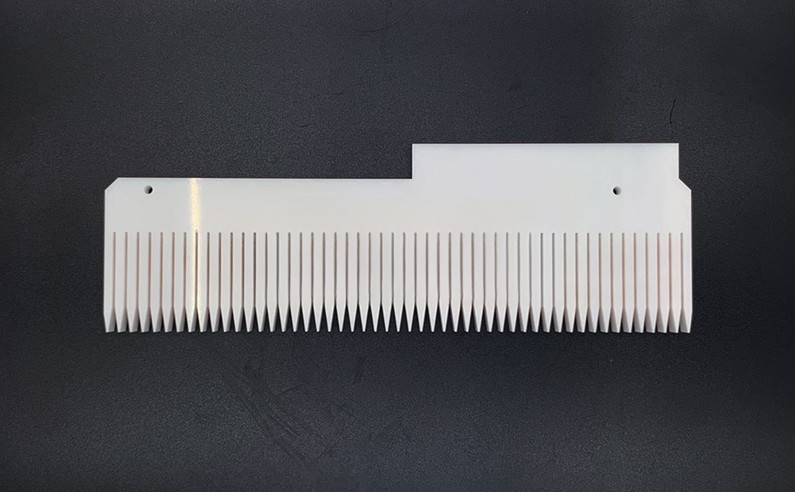

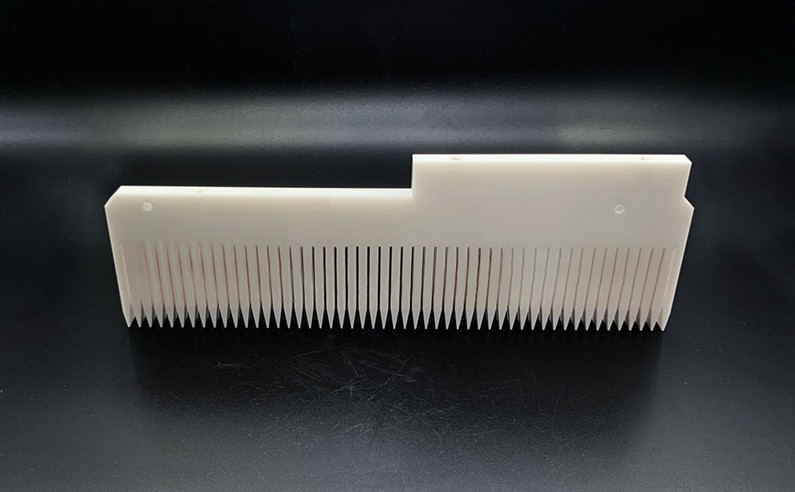

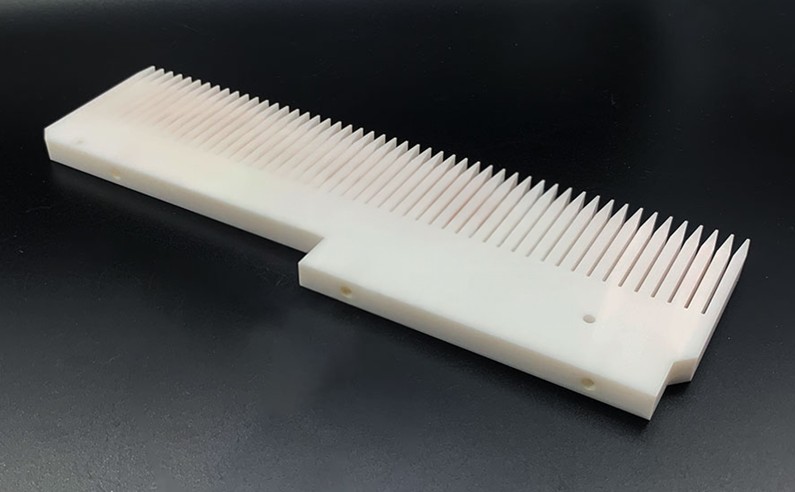

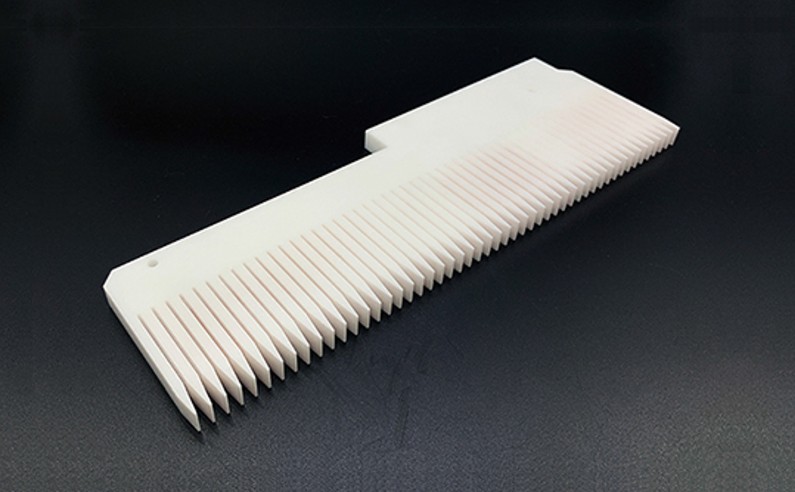

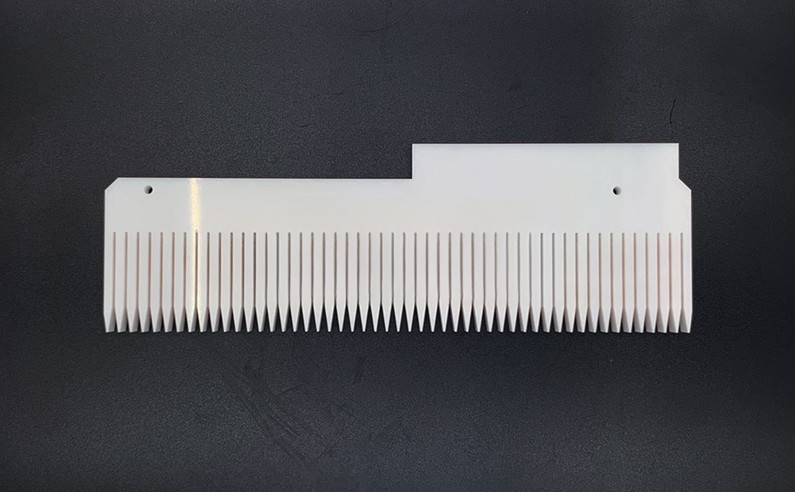

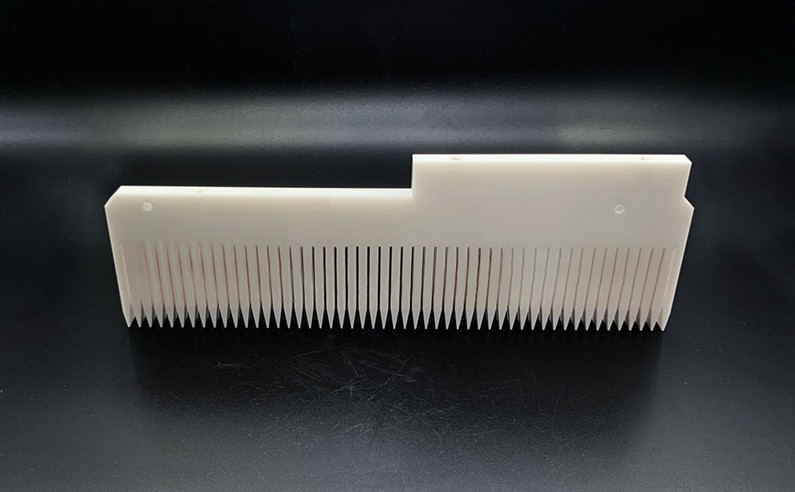

Zirconia Ceramic Comb

Zirconia ceramic comb, with five characteristics: wear resistance, insulation, corrosion resistance, high temperature resistance, and high precision, has become an irreplaceable key consumable for high-end manufacturing industries such as photovoltaics, electronics, and textiles. Especially in photovoltaic silicon wafer inserters, their performance directly determines production efficiency and product yield. In the future, with the breakthrough of nanotechnology and green manufacturing processes, cost reduction will promote it to replace traditional metal components in more fields. The following is a brief introduction to its specific application scenarios and characteristics:

Positioning combs for ultra-precision photovoltaic wafer inserters, anti-static conveying and positioning combs for PCB assembly or SMT pick-and-place machines/insertion machines, high-speed yarn guide combs for textile winders and doubling frames, fixture combs for wafer/glass substrate transfer equipment, sample separation combs for automated analyzers in medical laboratory devices, and guide combs for sorting and packaging machinery in food processing applications, etc.

Zirconia ceramics have the advantages of high toughness, high flexural strength and wear resistance, excellent thermal insulation properties, and coefficient of thermal expansion close to steel, so they are widely used in the field of precision structural ceramics. The main ones are: T-TZP grinding balls, dispersion and grinding media, nozzles, ball valve ball seats, zirconia molds, micro electric fan shaft-cores, fiber optic pins, fiber optic sleeves, wire drawing dies and cutting tools, wear-resistant cutters and other room temperature wear-resistant components, etc.

Product Photos:

Machining accuracy:

(1) Shaft: circularity 0.002 mm, concentricity 0.002mm, Roughness Ra0.1~0.02;

(2) Hole: minimum machining hole diameter 0.2 mm, depth up to 6 mm (parameters depend on specific materials);

(3) Groove (gap): a minimum of 0.1mm narrow grooves can be processed, as well as grooves of various shapes;

(4) Flat surface: the minimum thickness 0.1mm can be processed, parallelism 0.001mm, measurement tolerance 0.001mm, and roughness Ra0.1~0.02;

(5) Thread: Internal thread specifications machinable with M2 or above, and the thread accuracy up to GB-7H; External thread specification is not limited, and the accuracy GB-6g .

Welcome to Fudong Machinery Manufacturing (Hong Kong) Co., Ltd., we hope our products can suit your needs!

Founded in October 2006, Fudong Machinery is an enterprise specializing in the research and development, manufacturing and sales of non-standard industrial ceramics, cemented carbide (tungsten steel), and various metal and non-metal precision mechanical parts. After nearly 20 years of development, we have accumulated rich industry experience and trained a group of professional and technical personnel. It has a complete production process and quality management system, as well as a complete set of precision processing equipment and testing equipment, and has a good reputation in the industry.

At present, in the field of industrial ceramics, we specialize in the production of zirconia ceramic precision parts, alumina ceramic precision parts, silicon nitride ceramic precision parts, silicon carbide ceramic precision parts, machinable ceramic precision parts, microporous ceramic precision parts, aluminum nitride ceramic precision parts, cemented carbide (tungsten) precision parts, etc.

Applications:

Our products are widely used in precision machinery manufacturing, microelectronics, semiconductors, aerospace, biomedicine, optical fiber communication, testing and inspection, photovoltaic solar energy and other fields.

Product customization:

Non-standard parts customization, due to different requirements such as product size, material details, processing accuracy, etc., resulting in different costs such as material costs, processing costs, packaging logistics, etc. Please be sure to contact customer service when ordering, provide as much part information (drawings or samples, use environment, etc.) and your requirements (quantity, delivery date, etc.) as much as possible, and we will submit you a specific plan that meets your parts requirements, as well as a preferential quotation.